Confused? If you’re reading this page then I’m pretty sure you are. Dealing with numbers, values and calculations when machining or 3d printing can be hard for those just starting.

The lingo and terminology used by many people both online or at a new job can be hard to understand. My hope is that after this quick lesson in dealing with machine shop numbers, you will not only be comfortable reading your numbers and measurements but also will know how to perform some simple calculations using them.

Let’s begin

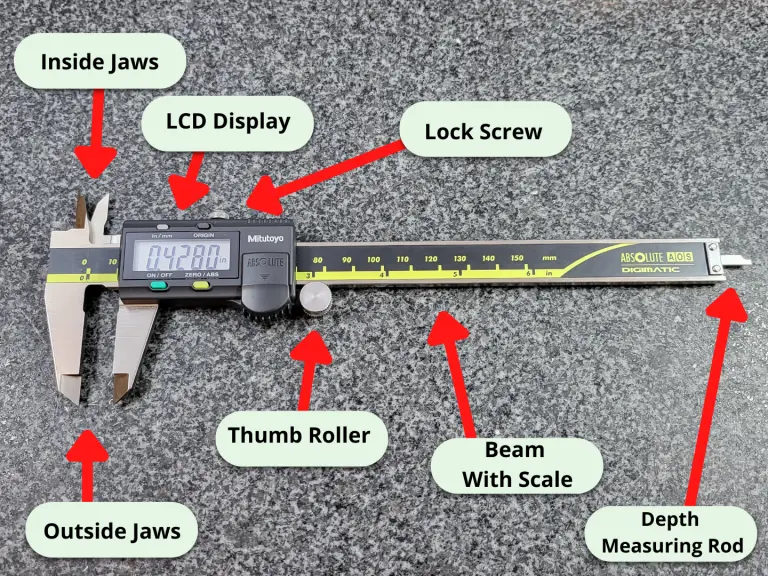

First we need to understand what the numbers we are working with represent.

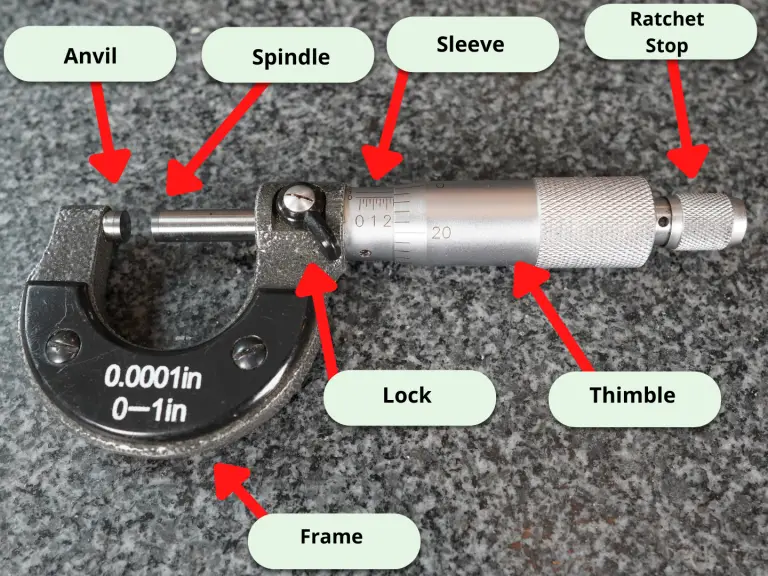

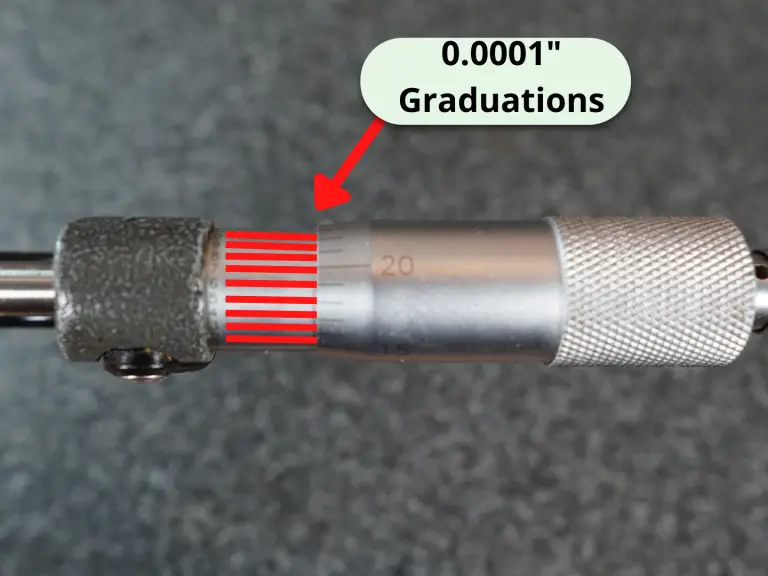

Whether they are a reading on a micrometer, a spec on a blueprint or a stack of gage blocks, the goal is the same.

We need to know how to read them and work with them.

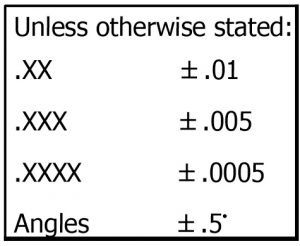

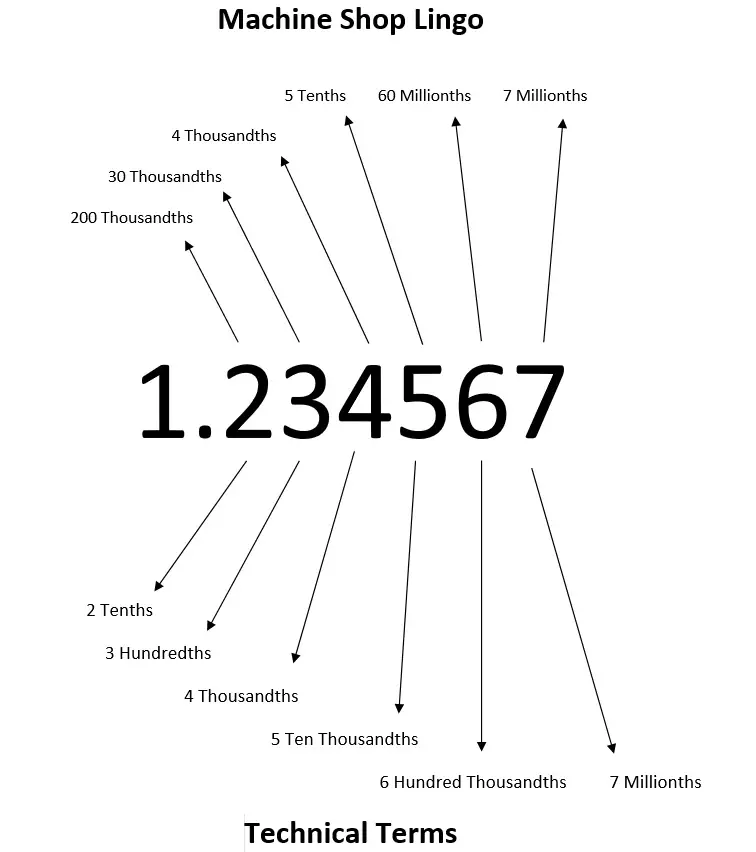

Below is a graphic that shows the name (including machine shop lingo) for different values.

Pay attention to how far each number is from the decimal place when looking at the chart.

Please note that not everyone will be working down to millionths of an inch but I included them for reference. Many will only work down to the the values shown in this table.

Value | Machinist Lingo | Technical Math Term |

0.001″ | Thousandth or Thou | Thousandth of an Inch |

0.0001″ | Tenth | Ten Thousandth of an Inch |

Keep in mind that all these numbers and terms apply to imperial units (inches).

How to say the value

Machine shops usually speak in terms of thousandths of an inch. Because of this when we describe the value to someone else we will read it a little different than you might expect.

As noted above, if we give the example of 7.489136″ a machinist would describe the value as 7 inch, 489 thousandths, 1 tenth, 36 millionths.

Read that last sentence over a couple times to really understand the terms your typical machine shop speaks in.

As a note, not all machine shops or hobbyists will deal in millionths of an inch and some might not even work with tenths but I have included them for reference.

Note: Thousandths of an inch is often abbreviated as “thou” especially when discussing values verbally.

Machine shop number reading examples

Below are some more examples to show how machinists communicate values:

Value | Machinist Lingo |

1.325″ | 1 inch 325 thousandths |

0.5001″ | 500 thousandths 1 tenth |

0.021 | 21 thousandths |

0.6532″ | 653 thousandths 2 tenths |

9.792345″ | 9 inch 792 thousandths 3 tenths 45 millionths |

Gage blocks

A common scenario for someone new in a machine shop is learning how to set up a stack of gage blocks.

I’m not going to show you how to pick the right gage blocks for your stack here. If you need those instructions then head over to Starrett’s website. They have great instructions that show you how to select your gage blocks and make a stack of a specific height.

The link also contains information related to the use and care of your gage blocks. Take care of your gage blocks people, those things are expensive.

How to setup calculations

Now I said I would show you how to work with these numbers, so let’s demonstrate how to do that.

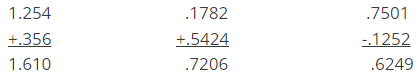

The important part when dealing with numbers or values in a machine shop context is to line up the decimal point. Below you will see some examples of addition and subtraction of numbers:

Simple calculation examples

For practice, let’s list out how to say those answers!

Value | Machinist Lingo |

1.610″ | 1 inch 610 thousandths |

0.7206″ | 720 thousandths 6 tenths |

0.6249″ | 624 thousandths 9 tenths |

There aren’t any other special tricks here. Once you line up the decimal places everything else is just like you learned early in school. Also consider yourself lucky we have calculators.

That’s it. Now you should know how to speak in terms that a machinist would understand and use the values in simple calculations.

If you need more in depth training when it comes to machine shop math, check out the training linked below. It breaks all the hard subjects down into bite sized pieces to make them easy to understand.

Ready to master machining math?

Get the tips and tricks you need to master the math needed for CNC and manual machining. Includes easy-to-follow guidance to make learning the math you need to succeed a breeze!