Table of Contents

ToggleWhat is a caliper?

A caliper is a measuring tool used to check precision measurements.

The biggest strength of calipers is how versatile they are.

Calipers come in many forms, including digital, dial and vernier versions.

They are commonly used to take measurements to an accuracy of .001″ or .01mm.

What are calipers used for?

Below is a list of the most common caliper uses:

- Inside measurements – hole sizes, slot widths

- Outside measurements – lengths, widths, diameters, thicknesses

- Depth measurements – depth of holes, slots, step locations

Types of calipers

There are three main types of measuring calipers. They are:

- Digital calipers

- Dial calipers

- Vernier calipers

They all perform the same types of measurements and to the same level of accuracy. The main difference between the three types of calipers is the display/scale that is used to read measurements.

The display/scales for each type of caliper are shown below.

Digital calipers

Dial calipers

Vernier calipers

Parts of a caliper

The parts are very similar on all three types of calipers; digital, dial and vernier.

You can see the slight differences in the pictures below.

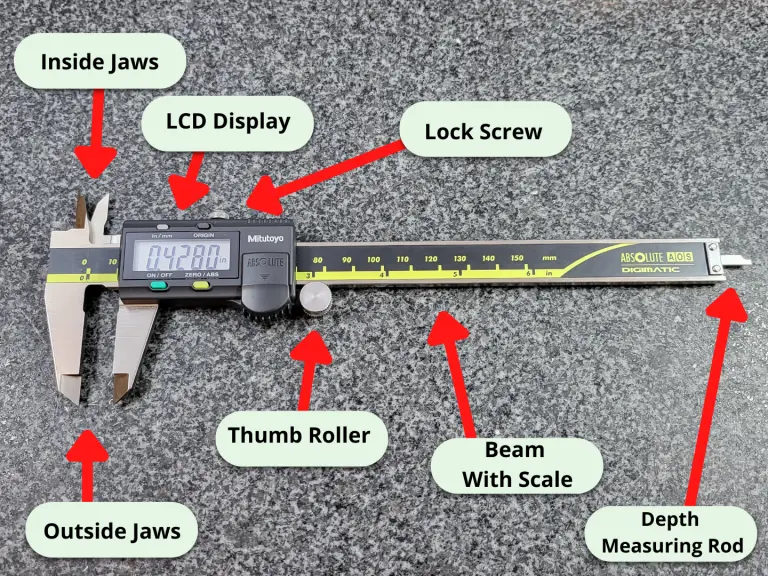

Digital caliper parts

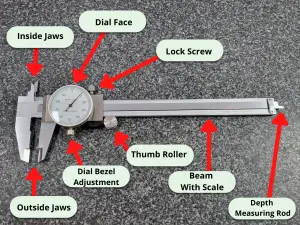

Dial caliper parts

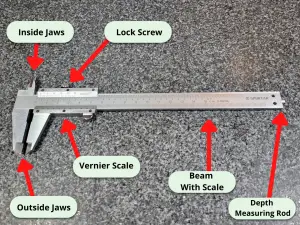

Vernier caliper parts

Calipers vs micrometers

Micrometers are another kind of precision measuring tool.

Micrometers are more limited in what they can measure. See the two types of measuring tools compared below.

Micrometers | Calipers | |

Accuracy | 0.0001" | 0.001" |

Measuring Range | 1" increments | 0-6" |

Types of Measurements | Outside Measurements | Inside, Outside & Depth Measurements |

How to use a caliper

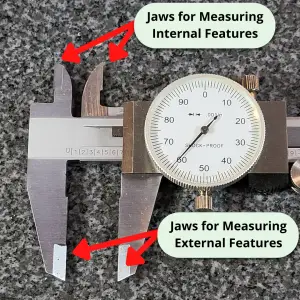

The most common type of measurement that calipers are used for is internal and external measurements.

To take a measurement with your caliper follow these simple steps:

- Before using your caliper, check to make sure that the measuring tool and surface to be measured are free of dirt, debris, chips, etc. The body of the caliper should slide freely along the scale or bar.

- For an outside measurement, slide the jaws of the caliper open until they are far enough apart to be placed over the part to be measured.

- Now proceed to close the jaws while trying to keep the jaws perpendicular to the surface being measured.

- Multiple measurements should be taken to verify that the caliper has yielded the true reading. For example, if a measurement is taken where the jaws of the caliper are not perpendicular to the surface being measured then the reading obtained can be larger than the true size.

Note: Do not exert a large amount of force on the caliper in the direction of measurement. This can cause the tool to flex and distort the true measurement. It is best to place the same amount of force that is used to zero the caliper.

How to read digital caliper

Reading a digital caliper is easy.

The digital readout display clearly shows the measurement value.

Because they are so easy to read, I highly recommend anyone who is looking to get started working with calipers starts with a good set of digital calipers first.

Digital calipers have the ability to quickly switch between metric and inch readings. Some also allow you to switch between fractional measurements as well.

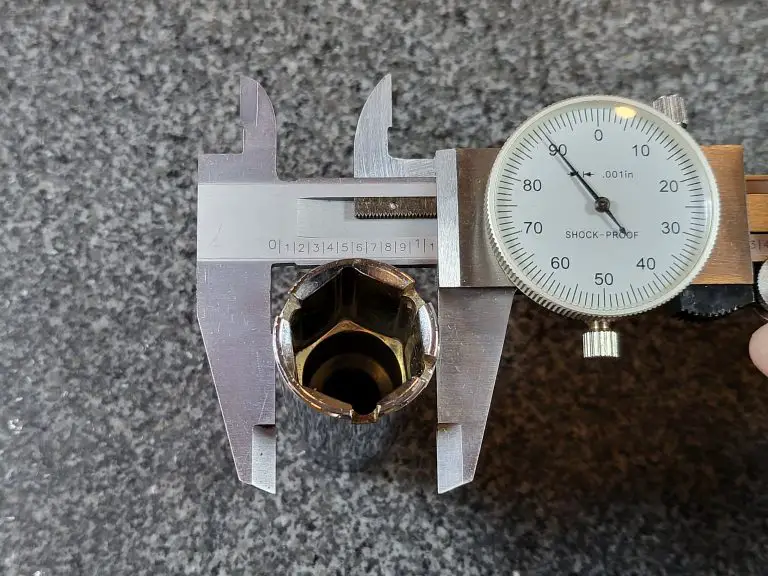

How to read a dial caliper

Reading a dial caliper is easy, though not as easy as a digital caliper.

Because costs have come down substantially in recent years, I recommend purchasing a digital caliper if possible.

If a digital caliper isn’t in the cards either because of budget or because you are working with an inherited tool then keep reading.

Dial calipers come in multiple varieties, but most have their measurement read in the same way. A reading is taken on the main scale and the dial face. The two readings are added together to get the final measurement.

Still need more info?

See our full guide to taking and understanding measurements with your dial calipers.

What makes a good caliper

Whether digital, dial or vernier, a good digital caliper needs two things: precision and accuracy.

Some adjustments can be made with most calipers to account for small errors in accuracy but nothing can be done to fix a tool that isn’t precise.

A quality caliper will move smoothly without any drag. This is the telltale sign of a good tool.

If your caliper ever feels like it is rubbing or dragging then it is most likely the result of damage from being dropped or contamination exposure.

Unfortunately if you caliper isn’t moving smoothly there isn’t usually much that can be done besides oiling the tool and sliding back and worth. Then wipe off the oil and repeat the process over again.

Make sure to consult the manufacturer’s instructions before performing this operation as calipers can vary and only use machine tool oil such as this one by Starrett.

Caliper calibration

Calibrating measuring tools such as calipers is important because it allows you to have confidence that your measurements are correct.

Check your calipers regularly to make sure they are accurate.

Related Articles

For more information check out these related articles: