Pros

Cheap

Not magnetic

Cons

No fractional mode

You get what you pay for in accuracy

Features

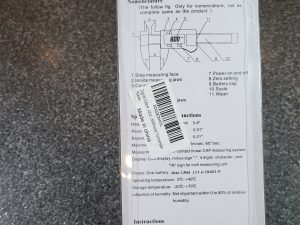

These digital calipers from Adoric feature your typical caliper measuring range of 0-6” or 0-150mm.

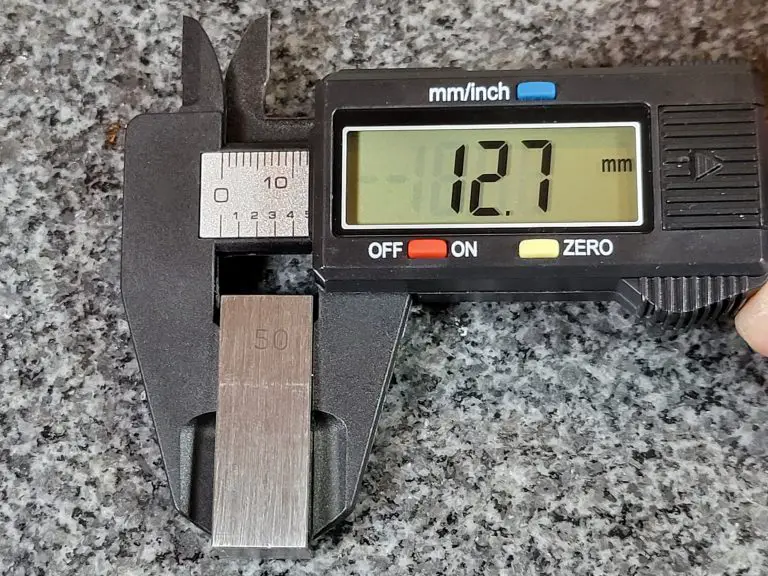

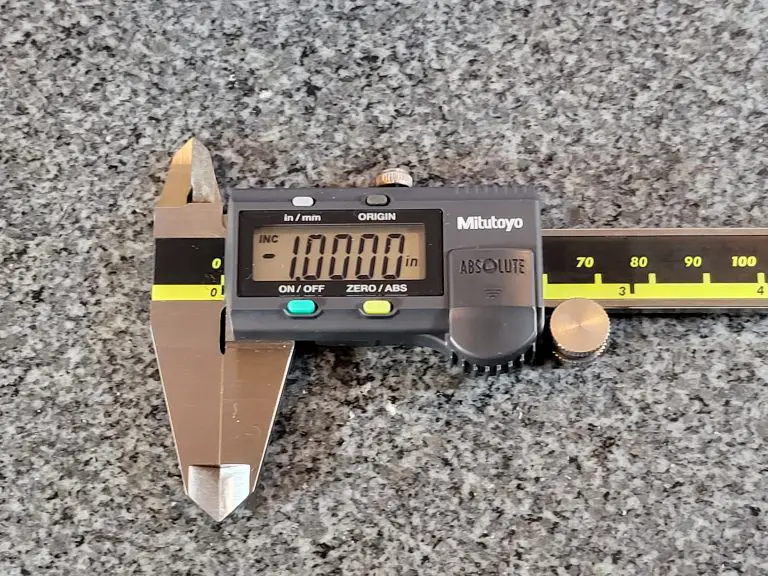

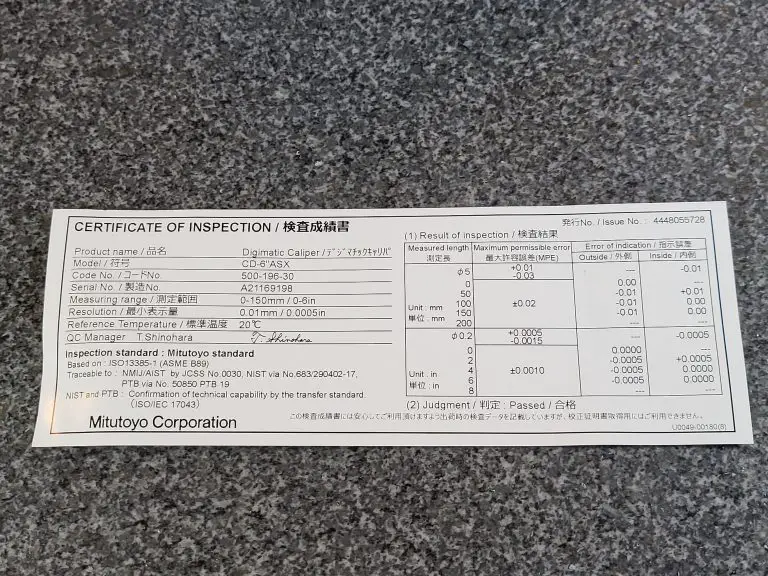

They have a claimed accuracy of +/- .010” or +/- 0.2mm. I tested this claim by measuring various gauge block sizes over their measuring range. I repeated this for inside, outside and depth measurements. In all measurements, the tool met its claimed accuracy.

Still, their accuracy isn’t great when compared to many other calipers but at the same time their cost reflects it. When you are buying a set of calipers in the neighborhood of ten bucks you can’t expect a lot.

For instance the packaging:

It screams kids toy more than it does precision measuring tool.

In fact, the packaging is so generic that the only mention of Adoric on it is on a sticker slapped on the backside. I’m pretty sure this means there are carbon copies of this same caliper being put out by other companies.

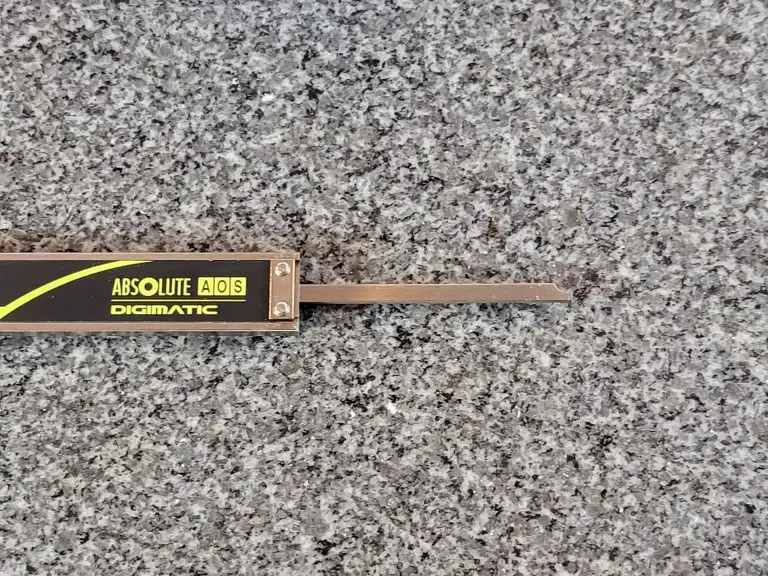

Carbon fiber copies might be more appropriate because that is what these calipers from Adoric are made of. They definitely don’t feel as rugged as metal calipers, but they don’t feel flimsy either.

The carbon fiber construction does have some benefits. Firstly, they are non magnetic which means measuring magnetic materials will be much simpler than with standard stainless steel calipers. It also means that these calipers are less likely to scrape or scratch your workpiece during measurement.

The nicest benefit of being made from carbon fiber is that they are extremely lightweight. I really thought these were going to be a cheapo tool, but the caliper has enough weight to make it feel strong while still being light enough to make it very easy to use one-handed and maneuver for all kinds of measurements.

Similar to most calipers, these Adoric digital calipers are capable of taking inside, outside, step and depth measurements.

These measurements can be taken in inch or metric readings. Unfortunately there is no fractional mode which in my opinion would be a nice addition considering their accuracy. A fractional mode that read to 1/64″ or 1/32″ would probably have worked well more many people.

Units are easily switched with the inch/mm button on the face of the caliper. A simple selection of buttons surround the easy to read display. Besides the inch/mm units button there is also an off/on and zero button.

Battery life is decent thanks to the tool’s ability to turn off automatically. When not in use, the caliper turns itself off after about 4.5 minutes.

The caliper also turns on automatically when it senses movement. So why even have an On/Off button? Use it or not, it’s there.

The Adoric caliper comes with an LR44 button cell battery already installed and a spare in the package.

One last note about the battery is that it is easily changed, possibly too easily. Many people have noted the battery cover accidentally coming off during use. I had not issues with the set I ordered for this review.

There is no ability to lock the caliper during measurement as seen on many other calipers. Additionally there is no protective case provided which is unfortunate but at this price point you can’t expect many extras.

Verdict

A nice alternative to your standard tape measure for shorter measurements. These calipers are a great tool for homeowners to take precise measurements.

Their accuracy is lacking but for many applications such as working with crafts or 3d printing, they will be sufficient. The most important thing will to know what type of tolerances you need to hold. Higher quality calipers will be usually be accurate to +/- 0.001″.

If you require more accuracy, but are on a tight budget check out the Neiko 01407A 0-6″ digital calipers. They make a decent alternative.

All-in-all for the price, these Adoric digital calipers are great to throw in a junk drawer or garage toolbox to keep handy for a quick and easy measurement.

Related Articles

For more information check out these related articles: