BobsCNC makes excellent CNC router kits all around. Unfortunately, while the Evolution 3 checks almost all of the necessary boxes you would hope for in a quality CNC router, it falls short in a couple key areas that ultimately end up holding it back compared to the competition.

However, if you have limited space and are looking for something with more power and capabilities than other entry level CNCs, the Evolution 3 may be the perfect fit. Read on to find out more.

Table of Contents

ToggleMachine Specs

Feature | Spec |

Work Area (Inches) | 16" x 18" x 3.3" |

Work Area (MM) | 406mm x 457mm x 85mm |

Machine Size (Inches) | 26" x 31" x 21" |

Machine Size (MM) | 660mm x 787mm x 530mm |

Weight | 32 Pounds |

Warranty | 60 Days |

Materials It Will Cut | Wood, Plastic, Aluminum, Acrylic, PCB, Leather & More |

Review

Pros

More power than most entry-level CNC routers

High-quality customer service

Cons

Limited work area for the price

Power and cutting capability

Let’s start with some of the best bits (CNC router humor, I’ll be here all day folks).

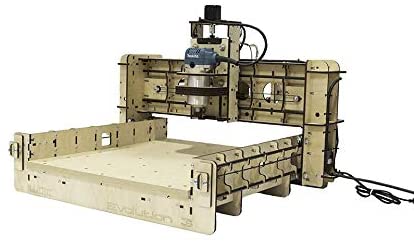

When it comes to build quality, BobsCNC has built a sturdy, rigid frame for this machine which makes it highly accurate. Combining its accuracy with the power of the included Makita RT0701C variable speed router means it can outpace the vast majority of entry level CNC routers.

While you shouldn’t expect an industrial grade machine, you will be able to drastically elevate the complexity of projects you are capable of creating, which is great for making better products to sell with your CNC.

All that power means that with some tweaking and experimenting, it is likely that you will be able to work with soft aluminum. This is not something that many machines are capable of handling. Still, if your new, make sure to work your way up to more difficult materials such as aluminum.

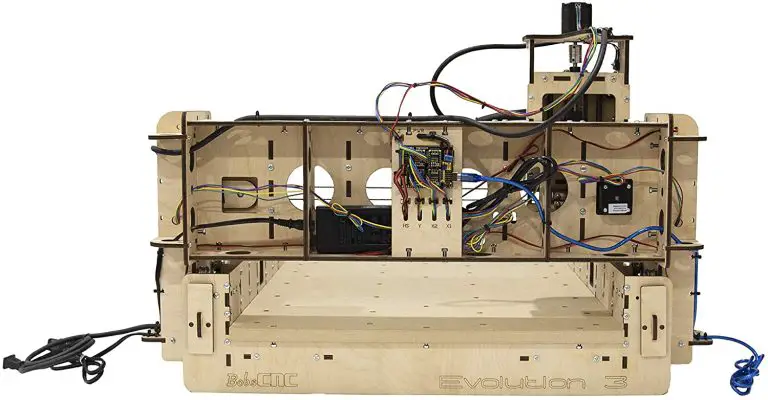

Assembly

Don’t expect to be cutting aluminum right out of the box. Actually, don’t expect to cut anything right out of the box. This is because the Evolution 3 is going to take you several hours to assemble.

You will need to assemble the machine entirely on your own. Fortunately, this shouldn’t be a problem because Bob’s machines are known for having extremely detailed and thorough instruction manuals.

A great benefit of the extensive assembly process is that you will become intimately familiar with all the workings of your new CNC. On a side note, if you do find yourself stuck, you can always hop on over to YouTube – there a many video tutorials available to help you put the E3 together.

YouTube is great for help but it is always great to be able to fall back to something more reliable. And, as always with BobsCNC, if you have any issues that you can’t resolve on your own, you can reach out to their customer service department.

Customer service

BobsCNC is well-known for being extremely helpful and responsive when it comes to technical issues. This includes initial setup and assembly as well as any operation issues you might run into down the road. Bob himself is even known to frequently return emails and phone calls to help customers who have questions.

Build quality

Now, you may be worried about buying a machine made out of wood to… cut wood. But there really is no need to fret. The Evolution 3 is made of baltic birch which is oftentimes used to make furniture because of its strength.

The Evolution 3’s components and frame are durable, and you’ll be able to repeat the same cuts and engravings over time with a high degree of precision.

Speaking of durability, the Makita router that comes with the Evolution 3 is a workhorse that will keep you cutting chips for quite some time.

Work area

Everything is great right? Well, up until this point at least. While the Evolution 3 is a solid machine, it does have some downfalls.

First is the work area. The Evolution 3 has a work area that is about 4.5 times larger than many other entry-level CNC routers such as the 3018 series of CNCs that are made by many manufacturers. Unfortunately, many will still find the size of the project they can complete a touch too small. Many CNC routing software packages are capable of tiling work so that you can work on longer projects, but you will still be limited by the width your router is capable of working with.

Compared to other CNC routers

The second and frankly, only other downside is the cost. The price point is about 2.5 times those 3018 CNCs we talked about and while this sounds fair when you think about the added capabilities, it bumps the Evolution 3 up into a slightly higher tier of machines.

At the Evolution 3’s price point it is competing with 6040 series CNCs as well as those from other well-known models such as the Shapeoko. In a strange decision, the stiffest competition is from BobsCNC’s next model up which is the Evolution 4.

The Evolution 4 has a significantly larger work area (24” x 24”) which allows a much bigger work piece to be cut. The machines are very similar otherwise and in all instances I would recommend going with the larger machine to allow you more versatility in what the machine is capable of.

Operation

Some may find the smaller size is easier to fit into their garage or workshop. The smaller machine isn’t quite portable like some of the 3018 CNCs but it is still fairly easy to move around. CNC machines – especially quality ones like the Evolution 3 – aren’t typically made to be moved around a lot, but if CNC is just a hobby and you’re working out of your garage or work shed, you may find it helpful to be able to easily move this CNC out of your way if you need to.

As far as actually running the machine goes, the Evolution 3 has an Arduino microprocessor that allows your computer and CNC to communicate. The grbl firmware, which comes preinstalled on the microprocessor, uses a USB port to receive information from the software on your computer.

The Evolution 3 is compatible with Windows, Linux, Raspberry Pi and OSX operating systems.

Conclusion

As an entry-level machine, the Evolution 3 is great CNC router.

Unfortunately, it stands in the shadow of its big brother machine, the Evolution 4. Both machines are well made and extremely capable.

You can save a few bucks if you know you won’t use the added machine work area but for most, I recommend stepping up in size to future proof your purchase.

Things to consider when purchasing a CNC router

Safety

While it may be fun to operate, this is a serious power tool. Treat it with the same respect you would give a table saw or something similar.

Wear eye and hearing protection. Dust collection is a great idea. Remember, that some materials can produce hazardous dust so be aware of the materials you should and should not work with.

Read your instruction manuals! They might save you a finger.

Work area size

Work area size is one of the most important features of any CNC router because it determines how large of a part you will be able to machine.

In most cases it will be best to go with the largest machine you can afford because many often find that they want the ability to make larger signs, engravings, etc. and can’t because their router physically cannot accommodate the item they want to work with.

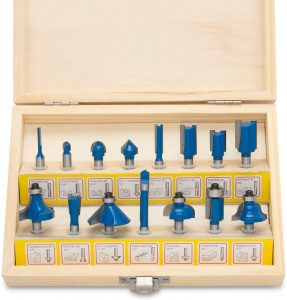

CNC routers vs spindles

When it comes to beginner level CNC machines, the terms router and spindle are used almost interchangeably. Some machines, such as the ones from BobsCNC, use an actual router like you would buy at a hardware store. Others use spindles.

Practically, they are both motors which have a collet or chuck to hold a cutting tool such as a router bit or end mill.

BobsCNC Evolution 3 vs Evolution 4

Specs | Evolution 3 | Evolution 4 |

Work Area (Inches) | 18" x 16" x 3.3" | 24" x 24" x 3.3" |

Work Area (MM) | 406mm x 457mm x 85mm | 610mm x 610mm x 85mm |

Machine Size (Inches) | 26" x 31" x 21" | 32" x 39" x 21" |

Machine Size (MM) | 660mm x 787mm x 530mm | 812mm x 990mm x 530mm |

Weight | 32 Pounds | 47 Pounds |

Warranty | 60 Days | 60 Days |

Materials It Will Cut | Wood, Plastic, Aluminum, Acrylic, PCB, Leather & More | Wood, Plastic, Aluminum, Acrylic, PCB, Leather & More |

In terms of overall capabilities, the two machines are relatively similar. They both have a torque of 75 in-oz and an AC power source of 600 watts. They also both use a Makita RT0701C router.

However, the Evolution 4 does provide you with a much larger workspace, and it’s quite a bit heavier than the Evolution 3. Really, if you’re trying to decide which machine is for you, just try to figure out the size of projects you’re working on or will want to work on in the future.

Also, think about the size of the space you’re going to keep the machine. Almost everyone has some limits on what they can fit in their workshop or garage.

Machining different materials

The Evolution 3 can work with and cut a large variety of materials including wood, plastic, soft aluminum, acrylic, PCB, and leather. The machine has ample power for most hobbyist projects. The biggest material that the Evolution 3 can not work with is steel. To work with steel, you will need a much more expensive machine. Industrial grade CNCs can quickly climb in price.

Assembly

As was discussed in the review, you have to completely assemble the machine yourself. Expect this process to take several hours, but don’t expect it to be too difficult. Though it’s time-consuming, the instruction manuals are highly detailed, and the YouTube tutorials and videos are extremely helpful.

Some other CNC router kits come partially pre-assemble which can be helpful but because many have awful instructions written in something between Chinese and English, they can end up taking almost as long to assemble.

Customer service

I touched on it above, but BobsCNC’s customer service is the best in the business.

If you have any problems at all – or even if you just want to run a project idea by them to get some input, don’t hesitate to send an email. In almost all instances, they will get back to you very quickly and give you a detailed answer. Bob himself might even give you a call or drop you an email!

Tooling

The router for these machines come with 1/8″ and 1/4″ spindle bits. You can use any straight, vee and rounded bits or buy them from various local and online retailers as long as they have shaft sizes of 1/8″ or 1/4″.

One add-on that is almost a must have, is some form of dust/chip collection. For many, this means using their shop vac along with a “dust boot” to clean up debris while the machine cuts.

Removing the chips will also help you obtain better finishes because chips can mar the surface as they are “recut” by the router.

CNC software

Bob’s recommends using a Universal Gcode Sender (UGS) software platform. This software can be found for free on Bob’s website. The UGS can communicate with the gbrl software that actually runs the machine.

The workflow will be to create your project in a software such as Fusion360 (also free!). The Fusion360 output will be put into UGS and then communicated to your CNC machine.

Final thoughts

BobsCNC produces some of the best CNC router kits available and the Evolution 3 certainly fits the bill.

It does lack a little in the work area category, which somewhat limits the projects you will be able to work on. While I do recommend going with the largest machine you can afford and also fit in your space, if the Evolution 3 is as big as you can go, you won’t be disappointed by it’s capabilities.

Related articles

For more information check out these related articles:

Love your website this was so helpful