What is a ballooned or numbered blueprint?

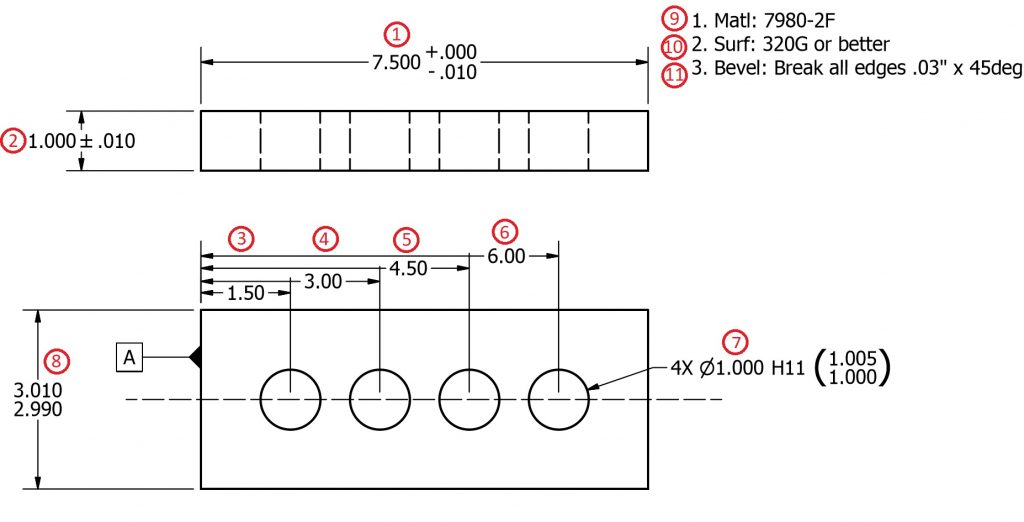

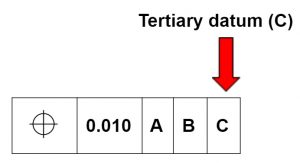

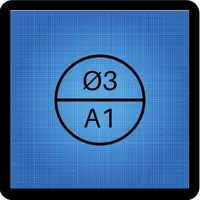

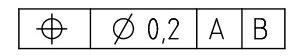

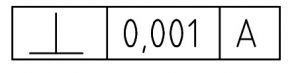

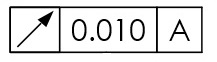

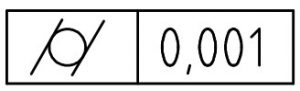

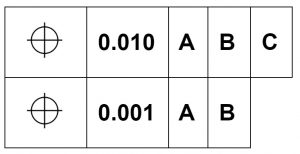

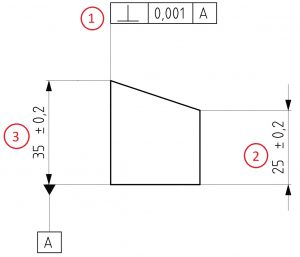

Commonly referred to by many different names including ballooned drawing, bubble drawing, numbered print, etc. A numbered drawing or blueprint is a way to identify individual attributes of a part or assembly as depicted in an engineering drawing. The numbers and balloons or bubbles are ordinarily done in red ink or a red font as seen above.

What are ballooned drawings used for?

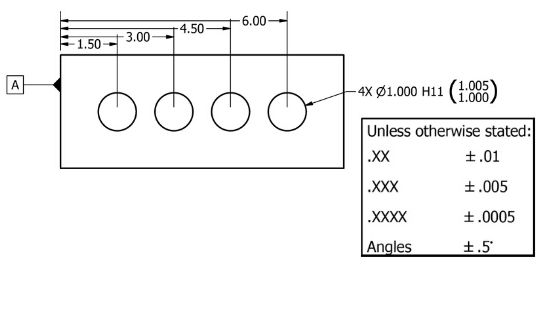

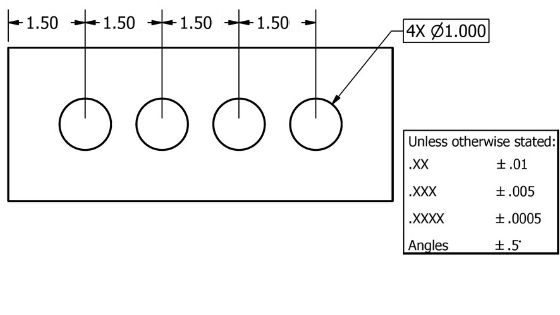

Numbered drawings are a common component in the inspection process. They can be a part of your in house inspection procedure or a requirement which you provide to your customers. Ballooned drawings are also frequently used as part of a first article inspection report package. They allow the reader to connect an individual measurement to its location on the blueprint. This is especially handy when multiple attributes with the same nominal values are present.

How to number a drawing

Numbering or ballooning a blueprint is a process that has some flexibility to the order in which attributes are labeled. The most important aspect is that all attributes are assigned a number including all notes and general tolerances as needed. When in doubt, number it. Where to start is a matter of preference but make sure that your numbering sequence is easy to follow. Generally the person numbering the drawing will start in the top left view and work their way clockwise assigning numbers to attributes in that particular view. This process is repeated for all views present on the drawing in a top to bottom, left to right manner similar to the way you read a book. Some users will list attributes in the notes first such as material, but this is simply a matter of preference. Just make sure to number all the relevant attributes in the notes. If you work in a logical manner, it will be much easier for the customer or reader to follow along.

What to include in a numbered drawing

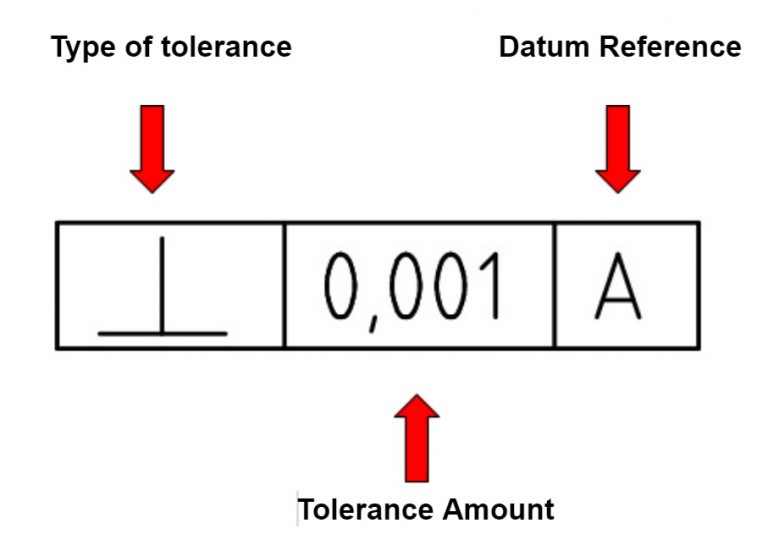

Assign a number to every attribute on the print including all notes and applicable general tolerances. Some notes may include more than one attribute in a single note which requires a numbered attribute.

Related Articles

For more information see these related articles: