What is a G85 CNC code?

A G85 command activates a boring and/or reaming canned cycle.

The steps the machine will take are:

- Rapid traverse to the R plane

- The machine will start boring/reaming from the R plane to the bottom of the hole (Z) at the listed feedrate (F)

- At the bottom of the hole, the machine will reverse directions and follow the same path back out of the hole using the same feedrate until it reaches the R plane

This cycle will feed into and out of the hole at a set feedrate.

Using a G85 command can lead to improved part accuracy as well as better surface finish. This isn’t guaranteed though and at times it may cause these same things to get worse.

The G85 canned cycle is very similar to G81. The difference is that G81 will rapid retract out of the hole. G85 will retract at the set feedrate.

Learn CNC Programming – It’s Easier Than You Think!

Learning G Code doesn’t have to be difficult…

If you know what to focus on.

Join our simple, easy-to-follow course, “G Code Made Easy: CNC Programming for Beginners“. We walk you through all the important codes – with simple explanations and real-world examples.

Want to become a super-skilled CNC programmer? Join now to take the shortcut to becoming a G Code Master today!

Make Learning G Code EasyOther codes used with the G85 code

There are many different parameters used in a G85 code. They are similar to those used in other canned cycles. See the list below to understand all the different parts of the code.

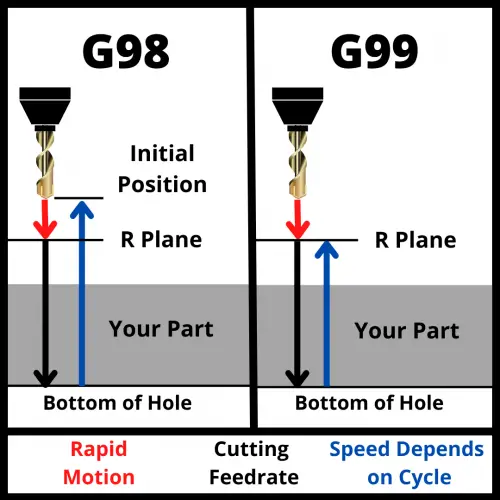

- G98 – Return to initial plane

- G99 – Return to R plane

- X – X axis location of the hole

- Y – Y axis location of the hole

- Z – the location of the bottom of the hole

- R – retract plane or R plane, the point where the machine will stop rapid movement and begin using the specified feedrate

- F – the feedrate for the boring action

- K – number of times to repeat the cycle

The retracting value (R) or clearance level refers to the plane perpendicular to the Z-axis where the tool can move safely from one hole to another.

The R value should be set so the machine will clear any and all obstacles including clamps, fixtures and the part itself.

G85 code format

G85 X2.0 Y3.0 R1.0 Z-5.0 F25.0

It would be easy to assume that the Z location is the location of the start of the hole. In reality, it is the Z location for the bottom of the boring/reaming movement.

Keep in mind that the X and Y coordinates of the hole are not usually in the same line as the G85 command.

In most programs you will see them in this format:

X2.0 Y3.0

G98 G85 R1.0 Z-5.0 F25.0

The program first identifies the coordinates of the hole and then starts the boring/reaming process.

How to cancel a G85 code?

The G80 code is used to cancel the G85 boring/reaming canned cycle. G80 is the code used to cancel all canned cycles.

If the G80 code is not used, the machine will attempt to bore/ream a hole at each new location given in the program.

When to use a G85 code?

The G85 code is useful in programs when a hole needs to be enlarged, a hole needs to be tapered (create an inner cone shape), or when a hole needs a high-quality finish to improve accuracy.

You need to understand that although reaming and boring are operated with the same command and tool (the reamer tool), they are not the same operation.

Reaming is just for finishing, while boring is used to change the shape of a hole by enlarging it or tapering it.

When not to use a G85 code?

The G85 command should never be used for drilling a hole because it can damage the cutting tool, the workpiece, and the operator.

A G85 code should be used on a hole which has already been drilled.

G98 and G99 when using a G85 code

Before applying the G85 code, the reamer tool should move first to a safe position above the reference (R) plane.

With most canned cycles it is best that the tool moves to a starting point first and then to a reference plane with either the G98 or G99 command.

When using the G98 code, at the end of the cycle the tool will go back to the starting point (above the R plane) in rapid movement after passing the reference plane.

When using the G99 code, at the end of the cycle the tool will only return to the reference plane after finishing the boring/reaming cycle.

What to think about when using a G85 code?

Hole size

The holes where the G85 cycle will be run should be drilled close to the final diameter size to ensure a good surface finish and increase the life of your cutting tool.

Speeds and feeds

The material to be machined and the required surface finish/roughness should be used to determine the appropriate speeds and feeds to use when machining.

Retract planes

There are two G codes which control how the machine will retract when using canned cycles such as G85.

The G85 code is most commonly used with the G98 code.

Retract planes are important because they control how your machine will act when moving between locations when using canned cycles such as G85.

Retract planes should be chosen so that the machine avoids any and all obstacles such as clamps, fixtures and the workpiece itself. More info about the type of retract planes that can be used is shown below.

Canned cycles that are similar to G85

G85 vs G81

The G85 and G81 canned cycles are very similar. The difference between the two is that the G81 cycle will retract out of the hole at the machines rapid speed.

G85 will retract out of the hole at the same feedrate that it fed into the hole.

G85 vs G86

The G86 canned cycle is used for boring and is similar to G85 except that it stops the spindle before retracting the tool. The spindle is restarted when it reaches the retract (R) plane.

Because the spindle stops when using G86, the cutting tool can leave a mark on the surface of the hole. For this reason, G86 is mainly used with roughing operations.

All three commands (G81, G85, and G86) are canceled with the G80 code.