What is the F code used for in CNC programming?

The F code, or feedrate command, controls how fast the cutting tool moves.

Feed rates set with the F code are used with movement codes such as G01 (linear interpolation), G02 (clockwise interpolation), G03 (counterclockwise interpolation) as well as various canned cycles.

The feedrate command is ignored with one movement code, G00 (rapid travel).

When the G00 code is used the machine moves at its max speed no matter what the feed rate was last set to.

The feed rate needs to be adjusted depending on the needs of the cutting process.

For example, the feed rate for machining aluminum will be different from the feed rate needed for hardened steel and so on.

Choosing the correct feed rate can mean the difference between a perfect part and a pile of scrap.

Learn CNC Programming – It’s Easier Than You Think!

Learning G Code doesn’t have to be difficult…

If you know what to focus on.

Join our simple, easy-to-follow course, “G Code Made Easy: CNC Programming for Beginners“. We walk you through all the important codes – with simple explanations and real-world examples.

Want to become a super-skilled CNC programmer? Join now to take the shortcut to becoming a G Code Master today!

Make Learning G Code EasyF code structure

The format for an F command is F3.0

Unlike some other commands, the feed rate code allows the use of decimal points.

One thing to be mindful of when using the F code is the feedrate unit mode.

Codes for setting feedrate unit modes

There are two types of feed rates that can be selected and the codes used vary between machine types.

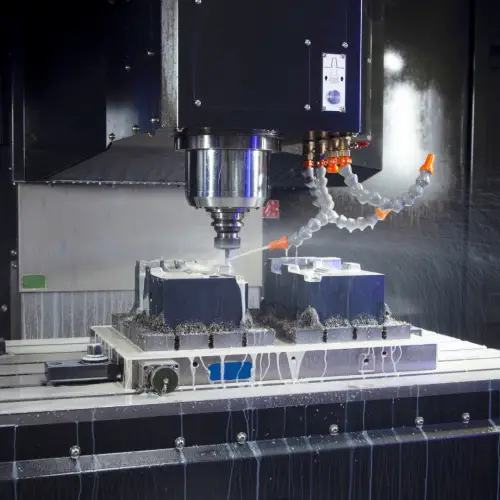

On milling machines:

G94 code: Sets the feedrate to inches or millimeters per minute.

G95 code: Sets the feedrate to inches or millimeters per revolution.

Milling machines are less likely to switch between the two modes. Many machines will be set to a feedrate per minute mode and stay in it.

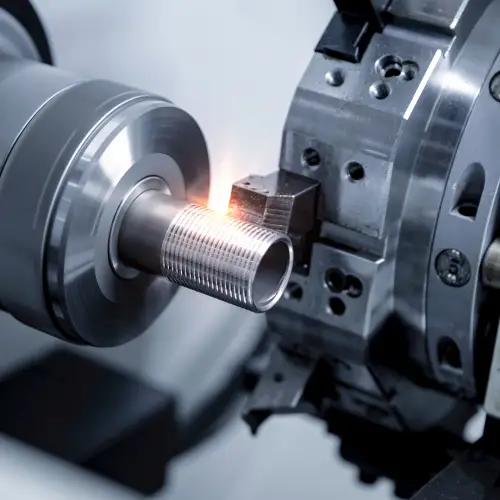

On lathe machines:

G98 code: Sets the feedrate to inches or millimeters per minute.

G99 code: Sets the feedrate to inches or millimeters per revolution.

Lathes are more likely to switch between the two modes. Feedrate per revolution is more commonly used in CNC lathe programs.

Feedrate units

Feedrate per minute (mm/min or in/min)

This type of feed rate sets the distance that the cutting tool will travel in 60 seconds.

This feedrate mode is more common when milling and does not depend on the spindle speed.

For imperial (inch) system units, the feed rate value contains one decimal place. For example, a feedrate of 12.5 inches per minute would be F12.5.

For metric (mm) system units, the feed rate value contains one decimal place, even if it is a whole number. For example, a feed rate of 200 mm per minute would be F200.0

Feedrate per revolution (mm/rev or in/rev)

This type of feed rate sets the distance the cutting tool will travel in one spindle revolution (rotation).

The feedrate mode is mostly used with lathes.

In imperial units, the feed rate number allows four decimals, while in metric units it allows only three decimals.

For example, a feed rate of 0.32945 mm/rev will be programmed as F0.329 and a feed rate of 0.08457 in/rev will be programmed as F0.0846 on most controls.

Most CNC machines can work with both types of feed rate.

However, feed rate per revolution is commonly used when working with a lathe and machining centers (mills) tend to stick with feed rate per minute.

Factors that affect the optimal feedrate

Many factors determine the best feedrate for your CNC including:

- Size of the cutting tool

- Material the cutting tool is made of

- Shape of the cutting tool

- Tool condition (sharpness)

- Workpiece material

- Coolant use

- Machine condition

- Spindle speeds

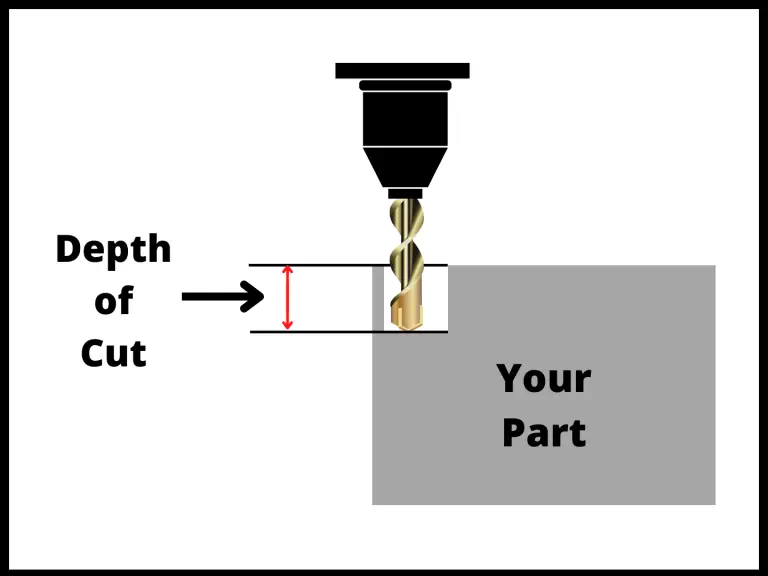

- Depth of cut

- Width of cut

Cutting tool

The size of the tool will directly affect the milling, turning, or drilling process in terms of motion and machining time.

Also, the tool material affects cutting speeds and feed rates.

High-speed steel tools support less friction, which means they generally don’t allow high feed rates and speeds.

Carbide and ceramic tools have better resistance and can be used at high speeds to increase machining efficiency.

The shape of the cutter and the angle of the tool also affect the cutting efficiency, and therefore the feed rate and speed.

Sharpened tools are ideal for reducing friction and chip load formation during cutting processes.

Workpiece material

Workpiece material has a similar affect to cutting tool material on feed rates.

The harder the material is, the more difficult it would be to cut it. Softer materials allow the fastest speeds and rates.

Materials such as titanium or stainless steel will cut very different than plastics or even aluminum.

Coolant

Proper coolant use can help reduce heat buildup, lubricate the cut and allow higher feedrates.

Machine condition

Backlash or wear are common in older machines which can require decreased feed rates and spindle speeds for safety reasons.

Spindle speeds

The speed of the spindle plays an important role in determining the best feed rate.

They don’t call it speeds and feeds for nothing.

There are many tables available online that suggest good starting points for picking the best spindle speed for different materials and machining processes.

Depth of cut

It should go without saying but if the depth of the cut and the feed rate are large, then the friction will increase causing tool damage.

In these cases, the cutting speed should be reduced. A careful balance needs to be maintained between cutting tool life and total machining time.

Width of cut

The width of the cut affects chip thinning during the machining process. Usually, increasing feed rates can decrease this effect and promote user safety.

How to calculate the feedrate

Figuring out your feed rate might mean doing other calculations first depending on what information you know.

You might need to switch between feed rate units or calculate the feed rate using the spindle speed.

Formulas for switching between units

In the formulas below, the following abbreviations are used:

- mm/min = millimeters per minute

- rev/min = revolutions per minute

- Nt = number of teeth on the tool

Feedrate in (mm/min) = Feedrate in (rev/min)*Nt*RPM

Feedrate in (rev/min) = Feedrate (mm/min) / (Nt*RPM)

Calculating feedrates

The formula for calculating feed rate is Fc = (*D*S)/1000

To calculate the cutting feed rate, you need to consider the variables shown below too:

- Fc = cutting feedrate

- D = Diameter of rotating part (job or workpiece)

- S = spindle feed

Always be careful to stay consistent with your units.

If you choose to work with imperial units, all the parameters involved in the equation need to be in imperial units. The same with working with metric units.

How to choose the appropriate feedrate

Many machinists struggle with establishing the appropriate feedrate for given machines and materials, and rightfully so considering all the factors involved.

Many rely on online databases, manufacturing catalogs, and CNC books such as Machinery’s Handbook or FANUC control guides.

There are also tables available online with feed rates and speeds according to the tool material, workpiece material, machine and controls used that can serve as a starting point.

Others use CAM software to get a hint of the speeds and rates needed for different machining operations.

And some experienced machinists have trained their ears to set the correct feedrate as a rule of thumb. This is a less accurate method and can easily lead to errors.

Whichever option you choose, it is important to have some guidelines for feeds.

Here are a few tips:

- Increase the cutting speed by following this sequence: carbon steel < speed steel < carbide. Carbide is the tool material that allows the highest speed.

- Increase the cutting speed by following this sequence: steel < iron < aluminum < lead. Lead is the workpiece material that allows the highest speed.

- Use the manufacturers specifications and charts to adjust the feed rates and speeds. The manufacturers have likely done extensive testing.

- You will usually be given a range of speeds and feeds depending on the tool and workpiece materials. Keep in mind that most of the time slower rates will mean longer tool life and less overheating.

Ways to change the current feedrate

Feedrate override

The feedrate override is a switch that can change the programmed feed rate from 0 to 200 percent.

The feed-rate override switch is located on the CNC control panel and it’s operated manually by the setup person or operator to slow (or stop) cutting motions.

Although feedrate override is useful in certain situations, you need to be careful to avoid tool overheating or breakage when using it.