What does a G73 code do?

G73 is a modal command that sets the CNC machine to run a peck drilling cycle.

The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole in a single pass.

G73 tells the CNC to retract a small amount after each peck. This helps break chips.

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!

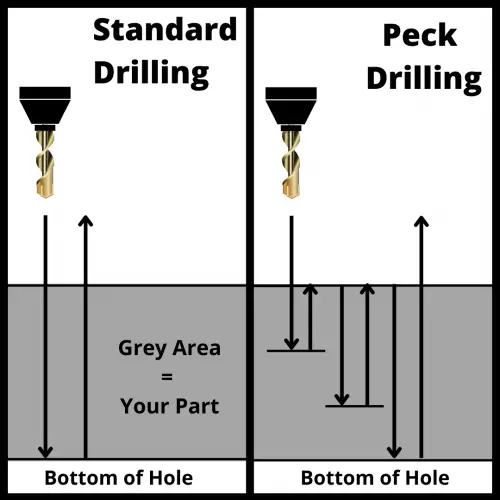

Difference between peck drilling and standard drilling

The main difference between peck and standard drilling is that the peck drilling process removes the material in multiple steps, while standard drilling is a one-step process.

Both commands are intended to make holes, but the peck drilling cycle allows more control over how the hole is drilled.

Peck drilling is the first option for CNC programmers when making blind holes.

The pecking process helps break chips as well as remove them and any other debris from the hole during the drilling process.

Trouble removing chips from the hole when drilling can cause size and/or surface finish issues.

Standard drilling is far more common when dealing with simple through (thru) holes.

Parameters used with a G73 code

- F – Feedrate

- R – Position of the R plane (clearance level)

- X – Hole position in X-Axis

- Y – Hole position in Y-Axis

- Z – Position of the Z Axis at the bottom of hole

- Q – Depth to increase on each depth

- K or L – Number of cycle repetitions

The feed rate (F) is dependent on the material that is being cut and the diameter of the drilling tool that you are using.

The retracting value (R) or clearance level refers to the plane perpendicular to the Z-axis where the tool can move safely from one hole to another.

Also, some machines might use L instead of K for cycle repetition (depending on the model and machine type). If you are the programmer, remember to check the machine’s manual for further details.

An example G73 code would look something like:

G73 X2 Y3 R1 Z-5.0 Q1.0 F25.0 L2

How to cancel a G73 code?

The G80 command is used to cancel a G73 code as well as all other canned cycles.

If the G73 command is not canceled, then the machine will continue to drill holes in every location given in the program.

Is the G73 code the same on a lathe as a mill?

No, the G73 code performs a different function on a CNC lathe.

On a lathe, the G73 code is used for a pattern repeating cycle. The machine will cut the same pattern multiple times, stepping in on each pass.

When to use G73 code?

If you want to make a shallow hole, you won’t probably need the G73 code.

There is no need for the tool to take on several pecks if the depth of the hole is less than an inch (depending on the material and tool).

The G73 command works best when you follow a general rule:

If the depth of the hole is 3 to 4 times greater than its diameter, use a peck drilling cycle such as G73.

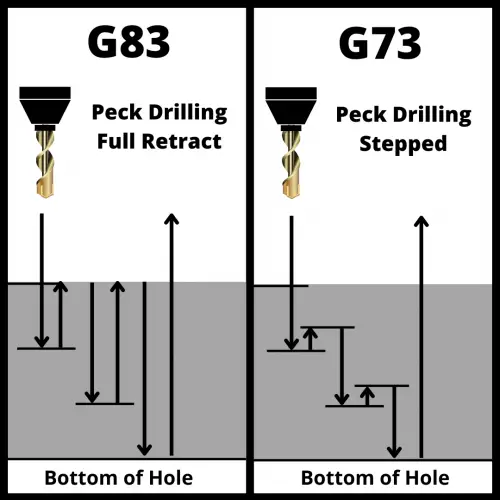

G73 vs G83

The most similar code to G73 is G83.

Both are peck drilling cycles with one key difference.

G83 will retract completely out of the hole after each peck to the retract plane. G73 will only retract to the start of each peck.

The G73 canned cycle is a peck drilling cycle but with a shorter retract intended for relatively shallow holes. Meanwhile, the G83 command is peck drilling with a full retract intended for deep holes.

Both commands are meant to help break and clear chips. G83 does a better job of this by fully retracting out of the hole but with the added expense of a longer cycle time.

On the other hand, G73 is designed to break up stringy chips, while G83 is intended to pull chips up and out of deep holes.

G73 vs similar codes

Besides G83 there are a few other G-codes for drilling holes with slight variations in the drilling process which make them better to use in certain circumstances.

Code | Name | Function |

Drill simple, shallow holes and center drilling | ||

Standard drilling cycle with a dwell at the bottom of the hole | ||

Drill into the part in steps (pecks) and after each peck, fully retract from the hole | ||

Similar to G83, but instead of retracting completely out of the hole, the machine will pull back a specified amount and then resume drilling |

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!