Somebody is going to get mad about this one. I just know it.

I have had many discussions with coworkers over the advantages and disadvantages of dial vs digital calipers.

What I have learned is that most people have a preference and that there isn’t anything that will change it. I am going to try and put aside any preference I have as I outline the differences between these two types of calipers.

Keep reading to find out more about the differences between digital and dial calipers. When you’re done, maybe you’ll have your own preference. But please, keep a more open mind than my coworkers.

Table of Contents

ToggleWhat is a dial caliper?

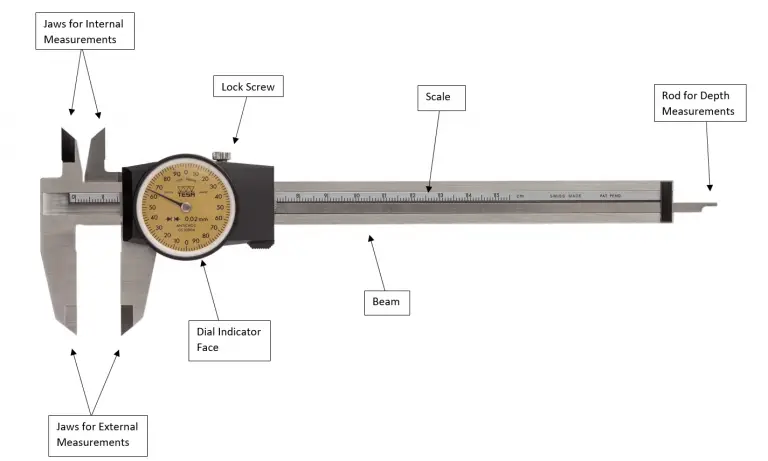

A dial caliper is a mechanical inspection tool for measuring sizes accurately. Most models are capable of taking internal, external, step and depth measurements to an accuracy of +/- .001” or +/- .02mm.

The most common variety measures from 0-6” but they come in many different measuring ranges including 0-4”, 0-8”, 0-12” and 0-24”.

They can take quick measurements and are a very versatile inspection tool. For many machinists, a set of calipers will be the most frequently used measurement device.

The biggest differentiator for a dial caliper is the rack and pinion system which drives the indicator needle seen on the dial face.

Advantages

- No batteries required

- Tried and true design

Disadvantages

- Can’t switch between inches and mm

What is a digital caliper?

Digital calipers are the same sort of inspection tool as a dial caliper. They have similar accuracies and are available in comparable measuring ranges.

The main difference is that digital calipers require batteries which power their LCD display. The difference in displays between a dial and digital caliper can be thought of as the same as the difference between a standard analog clock and a digital version.

Advantages

- Instant measurements

- Can measure inches and mm

Disadvantages

- Dead batteries

- Electronics susceptible to damage

Are dial calipers more accurate than digital?

This can be a tricky question to answer because there are so many different models and manufacturers of both dial and digital calipers out there. In saying that, the short answer is no.

When comparing dial and digital calipers from the same manufacturer there is generally no difference in the accuracy of the tool.

Are digital calipers easier to use than dial calipers?

Yes, digital calipers are easier to use than dial calipers. This is because the LCD display gives readings that can be instantly interpreted. Dial calipers require reading both the dial face as well as the scale to determine your measurement value.

Another added benefit of digital calipers that makes them easier to use is that most models are capable of switching between inches and mm at the push of a button. This saves the user from needing to convert measurements to another form of units.

This is an excellent feature for many users because it removes a step from the process which cuts down on the time needed to take a measurement. Removing the conversion step also eliminates the possibility that an error is made in the conversion calculation.

How to adjust or zero a dial caliper

To adjust a dial caliper, move the caliper until the jaws are closed.

Once in the zero position, check reading on the indicator needle. If it lines up on zero, then no adjustment is needed. You can proceed to verifying the tools repeatability as noted below.

If it does not line up on zero, loosen the bezel lock screw and turn the dial face until it lines up on zero. Once aligned, tighten the lock screw.

Now open and close the jaws to verify that the caliper repeatedly returns a zero reading.

Once this is verified, if available use a set of known reference standards such as a gauge block set to verify different readings across the calipers measuring range. For a 0-6” caliper, 0”, 2”, 4” and 6” would be a good start.

After the tool has been verified as accurate across its measuring range, you can proceed to take your part measurements.

How to adjust or zero a digital caliper

To adjust a digital caliper, move the caliper until the jaws are closed.

Once in the zero position, check reading on the digital display. If the display reads zero, then no adjustment is needed. You can proceed to verifying the tools repeatability as noted below.

If it does not read zero, press the zero button, sometimes identified as the origin button on some calipers.

Now open and close the jaws to verify that the caliper repeatedly returns a zero reading on its display.

Once this is verified, if available use a set of known reference standards such as a gauge block set to verify different readings across the calipers measuring range. For a 0-6” caliper, 0”, 2”, 4” and 6” would be a good start.

Once the tool has been verified as accurate, you can proceed to take your part measurements.

Things to consider when purchasing dial or digital calipers

Accuracy

Dial and digital calipers have comparable accuracies. There is some variation between makes and models of calipers, but most are accurate to +/- .001” or +/- .02mm. If you need something more accurate then you will likely need to look into purchasing a quality micrometer or micrometer set.

Most micrometers are accurate to +/- .0001” which makes them ten times more accurate than a typical caliper. The downfall is that they are more specialized and therefore are only capable of taking a single type of measurement (inside, outside, etc.) and have a smaller measuring range which is why a micrometer set is often needed to cover the measuring range of a single caliper.

Please note that cheap digital calipers often have reduced accuracy when compared to the usual gauge manufacturers such as Starrett and Mitutoyo. At the very least keep in mind the accuracy you need when purchasing because some of the budget priced tools are only half as accurate.

Measuring units

There are exceptions but most dial calipers are capable of measuring in a single set of units, either imperial (inches) or metric units (millimeters).

Some dial calipers are available that take measurements in both types of units, but they are clunky and often can not be calibrated so that both units are accurate. Stick with a single unit version.

Digital calipers are capable of taking measurements in both inches and millimeters while switching between the two at the push of a button. This is one of their primary advantages.

Many models are also able to take fractional measurements which can come in handy for some applications.

Measuring range

The measuring range of digital and dial calipers is similar. The most common version for both is a 6” caliper. Additionally, they can be found in ranges from 0-3” all the way up to 0-24” and beyond. Most will not find a need for measuring over 24”.

One point to keep in mind is that the cost goes up and the ease of use goes down as the caliper gets longer. For this reason, it is recommended to have multiple sets of calipers if you need to measure large sizes.

Imagine trying to measure a two-inch hole with a 0-24” caliper. It is going to be awkward and can easily lead to erroneous measurements. If you are in need of a set capable of measuring larger than six inches, then think about purchasing a quality 0-6” caliper as well as a 0-12” or 0-24” set.

The six-inch set will get the majority of the work and be easy to use and the larger set can be pulled out for use when the time is right.

Batteries

Dial calipers do not require batteries. This means they will always be ready to use, no matter how long they sit in your toolbox between uses.

Digital calipers on the other hand do require batteries and unfortunately not the types most people keep on hand.

Digital calipers typically use a LR44, SR44 or CR2032 battery. They are available at most department stores as well as online.

Modern digital calipers, especially the high-quality ones from Starrett and Mitutoyo, have extremely long battery life. Many people have reported going years between battery changes with a Mitutoyo digital caliper.

For peace of mind think about keeping an extra battery or two around in your toolbox or junk drawer if you decide to go with a digital caliper. This way it will always be ready to use when you need it.

Cases

Both dial and digital calipers are precision measuring instruments. You will find that most are built well and have no problem handling everyday use.

Unfortunately, the precision nature of these tools means that they are susceptible to damage from contamination such as coolant, oil, or metal chips as well as damage from physical shock.

A caliper that has been bumped off a workbench or dropped on accident can easily damage the jaws of the caliper or affect the internal workings resulting in invalid readings.

Calibration

Calipers should be calibrated periodically at an interval of your choosing. In a machine shop atmosphere, this will be determined by the company. Normal calibration intervals will range from 3 months to 1 year and everything in between. Some shops will even base the calibration frequency on tool use as opposed to length of time.

For home use, I recommend verifying them before each measurement.

With critical measurements, at home or in the shop, this verification becomes even more important. You don’t want to find out that your engine was bored oversize because you neglected to check your caliper before using it right?

Verify your tools and if possible check them against a known calibrated standard such as a set of gauge blocks.

For more info on caliper calibration, please see our post on the Complete Guide to Caliper Calibration.

Calibration certificates

Some of the caliper manufacturers and resellers offer a calibration certificate with their tool. My recommendation would be to skip this unnecessary add-on.

At a minimum you should be verifying your tool when you receive it. Ideally, you would calibrate the tool yourself with a set of calibrated gage blocks.

A calibration certificate will only serve as proof that the caliper was accurate at the time of calibration. Since many tools get ordered online or through a catalog, the tool will get be in a shipping company’s hand between the time of calibration and when you receive it. They aren’t always known for being gentle.

A calibration certificate doesn’t provide much peace of mind when buying a new tool. It should be accurate anyways, that is what you bought it for after all. It would be better to take the added expense of calibration and apply it towards a set of gauge blocks or other reference standard.

Depth base attachments

Depth measurements with a caliper can be quite tricky. The size and shape of the tool means it is top heavy and as a result it can be easy to get incorrect readings when taking depth measurements.

A depth caliper base attachment can help alleviate some of this by providing a wider, more stable base to take your measurements from. Adding one will make it easier to get consistent, accurate readings.

The base provides stability that is more in line with that of a depth micrometer, thought the tool will still be less accurate than a quality depth mic.

Related articles

For more information check out these related articles: