Table of Contents

ToggleHow important is math when working in a machine shop?

Math is something that anyone working in a machine shop will use on a daily basis.

The good news is that everything you need to know can be learned on the job and it isn’t too difficult.

Basic middle school level math skills can take you quite far with machining.

Find out which math skills are the most important and how to do them.

What type of math is used in machining?

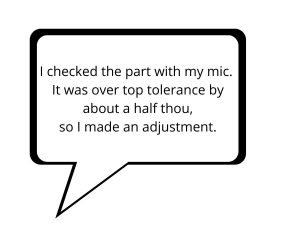

First, I want to point out that learning to speak like a machinist isn’t a math skill necessarily, but it is a skill that anyone working in a machine shop will need to have to do math in the shop.

Our guide to learning how to talk like a machinist teaches you the differences between machining terms such as “thou” or “tenth” and how they compare to normal math terms you may have already learned.

Now on to the real math!

Easy math skills

The math skills needed by a machinist are pretty simple, with a few exceptions. Luckily, a good calculator and a cheat sheet of common formulas (like the one provided below) will make almost all the math used in a machine shop easy enough for just about anyone to solve.

A large portion of the math you will need to do when machining is working with decimals. If you can do the following operations while working with decimals, you will have a solid start to learning machine shop math:

- Addition

- Subtraction

- Multiplication

- Division

Addition and subtraction are regularly used to calculate the top and bottom of your part tolerance.

Multiplication and division are used to convert between units such as taking a metric value and converting it into inches.

This is easy stuff to do with a calculator, which you should have by the way.

Speaking of calculators, I recommend going with an actual calculator and not just using your phone. You will look much more professional using an actual calculator. It won’t matter if you are using your smartphone for calculating setups and offsets, people are going to assume you are watching cat videos.

There are some good, specialized calculators for machining, but a cheap Texas Instruments calculator will do everything you need it to.

Unless you know you want a calculator with special functions for machining, it’s best to start out with something like a TI-30 series calculator.

One last easy one that helps is knowing how to calculate the decimal equivalent of various fractions. Again, this is simple to do with a calculator. Quick reference cheat sheets work well also.

Harder math skills

On to the fun stuff!

I say that jokingly because I know that many are scared to even say these words:

- Trigonometry

- Geometry

- Algebra

But they really aren’t that bad, especially because there are so many resources available to make them easier.

Take for example trigonometry.

Trigonometry is math for working with triangles. Sure, some people will use it frequently working in a machine shop, but there are tons of online calculators that basically make it a no brainer. And to top it off, you will only really use a handful of formulas anyways.

Geometry is no different than trig. Knowing where to find the formula or an online calculator is half the battle.

Most shops will have a trusty reference book such as Machinery’s Handbook or another good machining textbook available with all the formulas you will need. If not, luckily Google will usually turn up anything you need pretty quick.

Algebra is probably the most difficult math you will work with if you aren’t very good at math. A little bit of rearranging equations goes a long way.

And honestly, even if you will never be good at algebra, you can go pretty far in the machine trade.

There are multiple online algebra calculators/solvers to help you solve those equations without breaking a sweat. What did we do before the internet?

Lastly, statistics gets used in manufacturing, but in most instances this is something left to higher level engineers and/or management. It’s not something that anyone just starting out in a machine shop should be worried about.

What can you use to make machine shop math easier?

I touched on it earlier, but skip the slide rule and get a good calculator!

After that, bookmark some handy references whether they are online or in an actual book.

Lastly, just practice. The more you use the types of math that get used in a machine shop, the better you will get.

Bookmark the best resources and practice to master machine shop math.

If you want the easy button instead…

Focus on the most important stuff first.

You need to know how to do a limited number of calculations.

Hit the “easy button” for Machine Shop Math and find out what you really need to know.

Other resources

Common machining formulas

Speeds and feeds formulas – Make sure you don’t mix inches and mm! Always stay in the same units

- Feed rate (inches per minute) = RPM x feed per tooth x number of teeth/flutes in cutter

- Surface feet per minute = RPM x diameter of cutter / 3.82

- RPM = surface feet per minute x 3.82 / diameter of cutter

- Inches per Tooth = inches per minute / RPM / number of teeth/flutes in cutter

Conversion formulas

- Inches = mm / 25.4

- MM = inches x 25.4

- Diameter = radius x 2

- Radius = diameter / 2