What does the T CNC code do?

On most CNC machines, the T code tells the machine the tool to place in the tool changer to prepare it for a tool change.

The M06 command will then perform the tool change.

On some CNC machines, the T code will actually switch to the tool called out.

The T command is a very important CNC code because most programs will use multiple tools during the execution of a program.

It is not uncommon for dozens of tool changes to be performed in the process of running a more complex program.

When does the T code get used?

The T code is used at the start of a program to make sure the correct tool is loaded before any machining is performed.

After this initial setup, the T code is used every time the machine switches to a new tool.

If tool #1 is currently in the CNC spindle, calling tool #2 with the T02 command will ready it in the tool changer. Using the M06 command will swap tools.

Readying the tool before the switch saves precious machining time, something that is more important for high volume production machining.

Even though the tool is already loaded in the tool changer, it is advised to still call the T02 command in this instance to make sure that the correct tool is loaded.

The code would look like this:

T02

<machining code here>

T02 M06

Again, this format is used to ensure that the correct tool is placed in the CNC spindle during the tool change.

Without using the T02 command right before the M06 tool change command, it is possible that another is loaded in the tool change position and will be swapped in.

Imagine if you needed to re-run a portion of the code and started your program after the initial T02 code. If you didn’t repeat the T02 code right before the tool change then the machine would use the last tool number from its memory.

There is a good chance that it isn’t swapping the correct tool which can mean a machine crash.

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!

How to change tools

CNC cutting tools are changed using the M06 command. On some machines (usually older CNCs), the T code will cause the machine to perform a tool change.

Check your machine manual to know how your machine will react.

If your machine is equipped with an automatic tool changer, then it is likely that you will be using the M06 command to change tools.

Where should you document your tools?

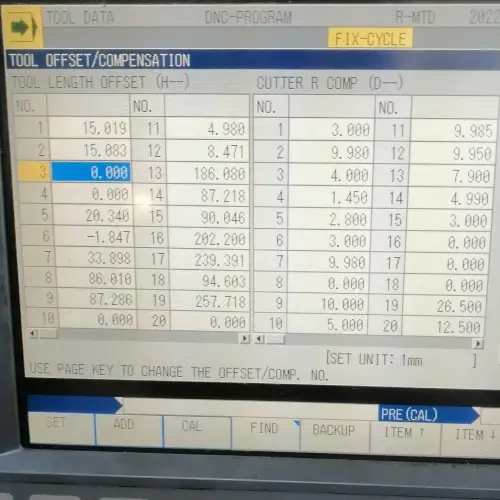

Information about your tools should be stored in two locations, on your machine setup sheet and in your tool offset library.

The setup sheet is used to communicate to the machine operator what tools are expected to be loaded in the machine while running the program.

The tool offset library, sometimes called the tool offset table stores information related to the size of your cutting tools. This includes both the diameter (D offset) and tool length or height (H offset).

The D offset and H offset values allow the machine to compensate for the size of the cutting tool and accurately machine the part.

Offsets and your cutting tools

Two of the most important characteristics of your cutting tools are their length and diameter.

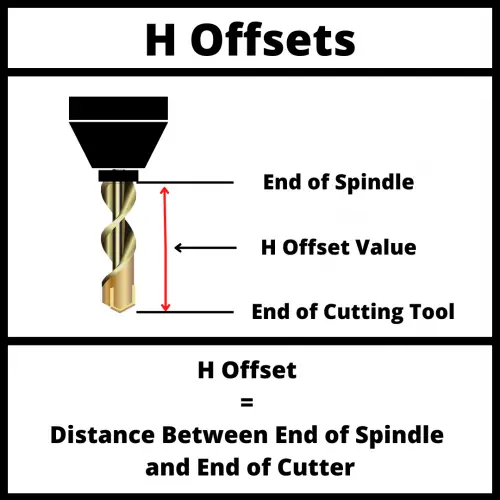

These two characteristics are stored as H (height) and D (diameter) offsets.

Knowing these two values and storing them in your offset library allows the machine to adjust for the size of the cutter when running the program.

Without these adjustments using height (H) and diameter (D) offsets, the program would need to be rewritten for each new tool. Not the most efficient way to machine parts.

The value of the H offset is the distance between the end of the spindle and the end of the cutting tool.

The H code is used to select the H offset stored in the offset library when tool length compensation is turned on with the G43 code.

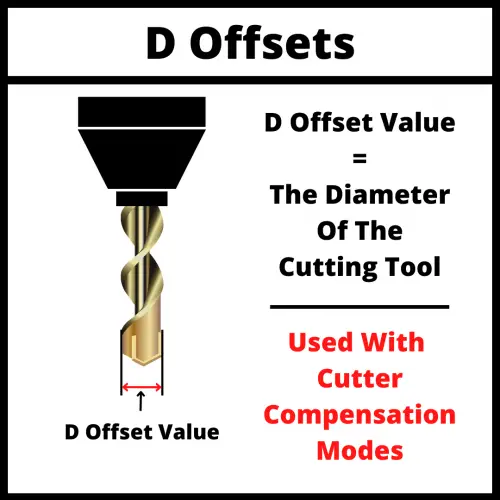

The D code is used to choose the D offset to be used when cutter compensation is turned on with either the G41 – Cutter compensation left or G42 – Cutter compensation right codes are used.

The D offset value is a number stored in the offset library that tells the CNC the size (diameter) of the cutting tool.

Once the machine knows the size of the cutter it can adjust how it runs the program based on that size.

Frequently asked questions about the T code

How is the T code used differently on mills vs lathes

As stated above, most CNC milling programs will use more than one tool to complete the machining of a workpiece.

Therefore, using the T code for tool changes is necessary.

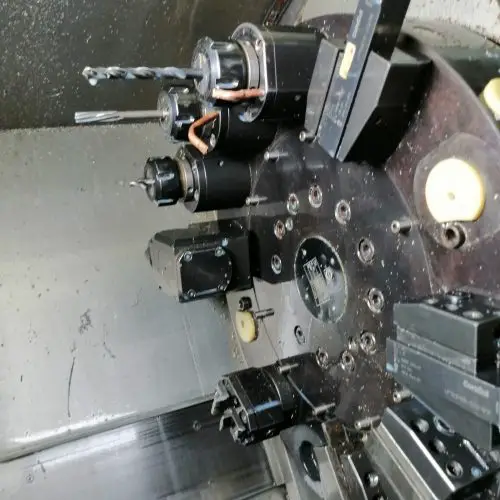

On lathes, the T change is used less often because the same cutter can perform many turning operations.

However, operations such as parting-off, threading, and drilling require specific tools. The number of tools allowed on a CNC lathe depends on the number of cutters that fit in the machine’s turret.

What does T0X.0X mean?

You may see some codes that have two numbers separated by a dot along the T code (e.g. T01.01).

This formatting exists because some controllers such as Fanuc allow different offsets to be assigned to the same tool.

Depending on the type of operation performed by the tool, you may need to change its offset values. T01.01 is tool #1, offset 1. T01.02 would be tool #1, offset 2.

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!