Which codes control coolant use on a CNC machine?

There are three main CNC M codes which control coolant use:

M07, M08 and M09.

M08 and M09 are the most common codes used.

In addition, many machines have special coolant functions available such as through spindle coolant.

Special coolant codes tend to vary from machine to machine so make sure to check your individual machine for specialty coolant function.

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!

M07 [mist coolant]

The M07 code is a modal command which turns on mist coolant.

Mist coolant is compressed air and coolant (usually oil).

It can be more efficient than flood coolant and in some situations be better at clearing chips than flood coolant, but it is used far less often than flood coolant with the M08 command.

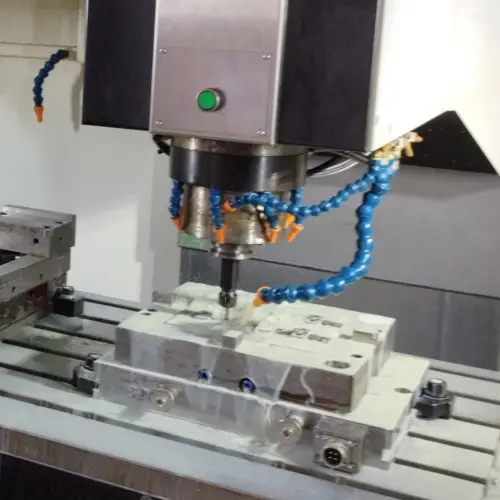

M08 [flood coolant]

M08 turns on the coolant for the main spindle.

In general, you will find this coolant aimed directly at the cutting edge of the tool.

Flooding the area with coolant has multiple benefits. The coolant reduces the heat build up from the cutting action, lubricates the cutter and helps to clear chips from the cutting area.

These three benefits of using flood coolant all work to reduce any heat that is caused by the cutting action which helps extend the life of your cutting tool.

M09 [coolant off]

The M09 code is used to turn off both types of coolant flow.

You never want to turn off coolant while the cutter is still cutting. On the opposite end of things, you should never turn coolant on if the cutter is already cutting.

Always start and stop coolant flow when the cutter is not actively engaged with the part.

What is coolant used for in CNC machining?

Coolant for CNC machines is used to keep the workpiece and cutting tool at a lower temperature during the cutting process.

Both the cutter and the part tend to get hotter because of the friction created cutting.

Coolant is also used to clear chips from the cutting area. If chips are not cleared from the cutting area then you can end up recutting chips. Built up chips can also lead to built up heat which can damage your cutter or part.

Recutting chips also has a tendency to create poor surface finishes.

Types of coolant that can be used

The main types of coolant used on CNC machines are:

- Air: This type of coolant reduces heat and clears the chips, but it does not lubricate the workpiece. This type of coolant is used more often with sensitive materials.

- Mist: With mist coolant, the pressure of the coolant is kept low and less coolant is used. This can be beneficial if your CNC doesn’t have a coolant capture system. Mist coolant lubricates the cutter and clears chips.

- Flood: This is also a low-pressure form of coolant. Flood coolant lubricates, removes chips and reduces heat buildup.

- High pressure: High pressure coolant is similar to flood coolant. The only difference is that it hits the workpiece at greater than 1000psi. The higher pressure and higher quantity of coolant helps cool the cutter better and remove more chips.

- Through spindle: Through spindle coolant delivers the coolant directly where it is needed. It is better at clearing chips in many cases because the coolant from the spindle pushes the chips out of a hole or pocket.

What is CNC coolant made of?

Coolants are categorized into four groups depending on the material that they are made of:

- Synthetic fluids: They are made of lubricants and rust inhibitors usually dissolved in water. It is basically soluble oil mixed with water to create coolant.

- Semi-synthetic fluids: These coolants are a mix between synthetic polymer and oil.

- Soluble oils: They contain a mix of 40 percent or more of oil and the rest is water.

- Straight oils: These ones are derived from petroleum, they are not diluted with water.

List of common CNC coolant brands

There are many different brands of CNC coolant available. Some of the most commonly used ones are:

- Castrol

- Chem Arrow

- ChemTool

- Fuchs

- Hangsterfers

- Master Fluid Solutions

- Quaker Houghton

- Qualichem

- Tower Coolant

- Yushiro

Frequently asked questions

Does every CNC machine have coolant capabilities?

Yes and no.

You can expect that industrial level CNC machines will have coolant capabilities.

Home or hobbyist level machines such as CNC routers often do not have coolant capabilities, but they can usually be added on if needed.

Which code turns CNC coolant off?

The M-code to turn coolant off is M09.

However, there are other stopping commands that also turn off coolant such as:

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!