The M09 M-code turns off the CNC machine’s mist and flood coolant functions.

This shuts off the “normal” coolant flow.

Other types of coolant, such as through spindle coolant, usually have their own code for turning the specialized coolant functions on and off.

Advantages of using coolant

The three main advantages of using coolant with your CNC machine are:

- Lubricate the cutter

- Clear chips

- Reduce heat buildup

M07 [mist coolant] vs M08 [flood coolant]

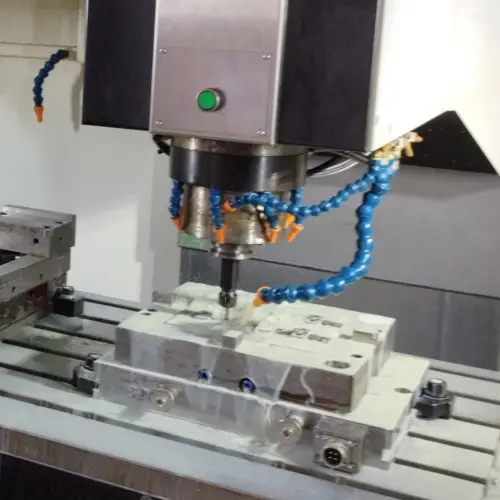

The most common type of coolant used in CNC machining is flood coolant with the M08 code.

Flood coolant is where the cutter and workpiece are literally flooded with the coolant fluid.

This works to lubricate the part, remove chips, and reduce heat buildup.

Mist coolant combines the coolant fluid with compressed air and sprays it on the cutting area.

Mist coolant uses less coolant fluid and can be less messy depending on your CNC setup, but it isn’t as good at reducing heat buildup as flood coolant is.

Mist coolant is activated with the M07 code.

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!

What are the other options for using coolant?

We discussed mist and flood coolant above but there are other options available as well including:

- Air: This type of coolant reduces heat and clears the chips, but it does not lubricate the workpiece. This type of coolant is used more often with sensitive materials.

- High pressure: High pressure coolant is similar to flood coolant. The only difference is that it hits the workpiece at greater than 1000psi. The higher pressure and higher quantity of coolant helps cool the cutter better and remove more chips.

- Through spindle: Through spindle coolant delivers the coolant directly where it is needed. It is better at clearing chips in many cases because the coolant from the spindle pushes the chips out of a hole or pocket.

Things to consider when using the M09 code

You never want to turn off coolant while the cutter is still cutting.

On the opposite end of things, you should never turn coolant on if the cutter is already cutting.

Always start and stop coolant flow when the cutter is not actively engaged with the part.

Which other CNC codes turn coolant off?

The main M-code to turn coolant off is M09.

However, there are other codes that turn off coolant as part of their function including:

Frequently asked questions about the M09 code

Does every CNC machine have coolant capabilities?

Yes and no.

You can expect that industrial level CNC machines will have coolant capabilities.

Home or hobbyist level machines such as CNC routers often do not have coolant capabilities, but they can usually be added on if needed.

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!