Key Points

- Rapid traverse is full speed movement

- Rapid travel and rapid traverse are the same thing

- The G code for rapid traverse is G00 on CNC mills and lathes

- The rapid speed can be adjusted using the rapid override

What is rapid traverse?

Rapid traverse, sometimes referred to as rapid transverse or rapid travel, is used for moving a machine tool around the workpiece as fast as possible.

Depending on the type of machine tool, this is accomplished in different ways. See below for more information related to CNC and manual machines.

How fast does the machine move in rapid traverse?

First let’s talk about speed.

Rapid traverse speeds vary based on the machine. A good quality desktop CNC will usually be capable of speeds around 100 inches per minute (IPM).

Larger, industrial grade CNC can often move at speeds of 1,000 inches per minute or more.

No matter what type of CNC you are using, you will want to make sure that nothing is in the way when these moves are being made in a CNC machine.

Crashing a CNC at normal speeds is bad enough, crashing a CNC at rapid speeds could be catastrophic.

Can rapid traverse speed be adjusted?

Most CNC machine controls have an adjustment to dial back the rapid travel speed. This is often referred to as Rapid Override or something similar. This override allows the CNC operator to adjust the rapid speed, usually in the form of a percentage of the full speed.

Some shops need to run full speed. Time is money after all, but many machine shops will dial things back a little for safety.

How does the CNC move during rapid travel?

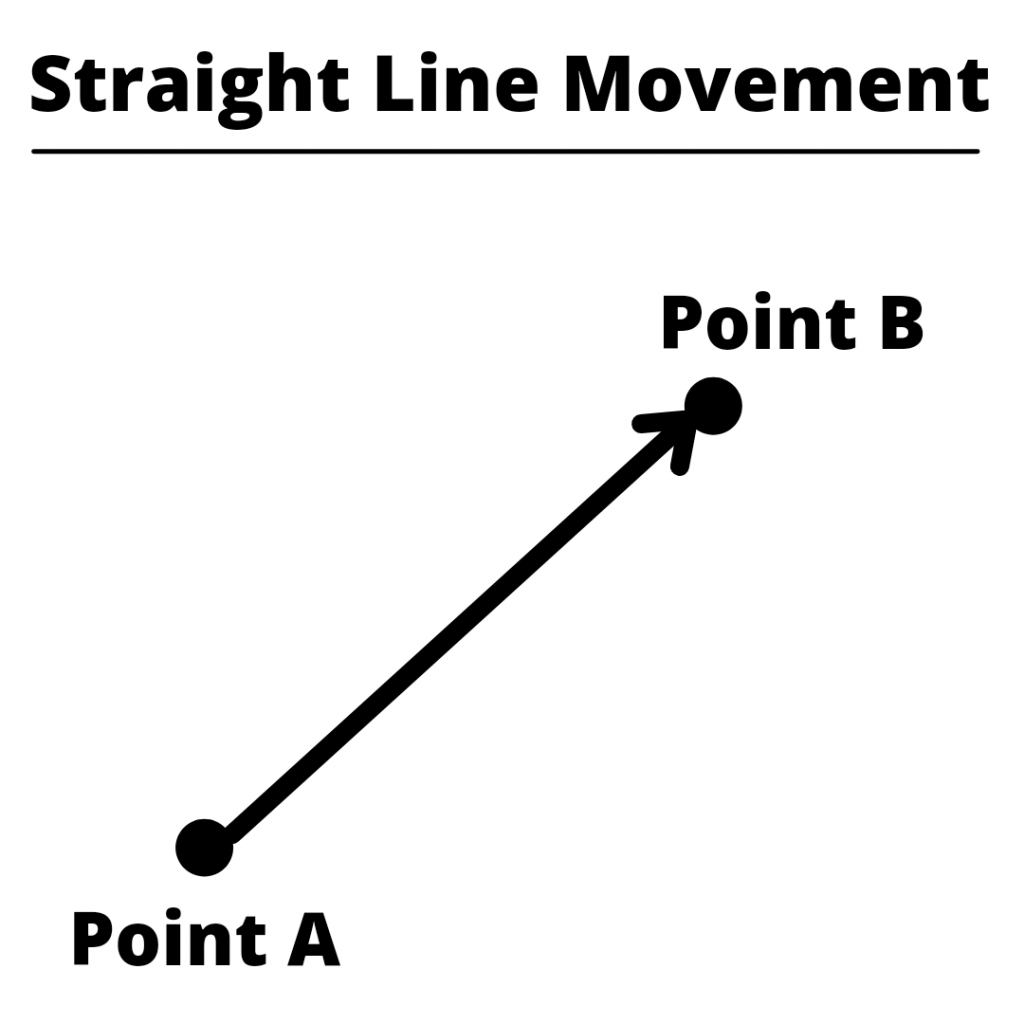

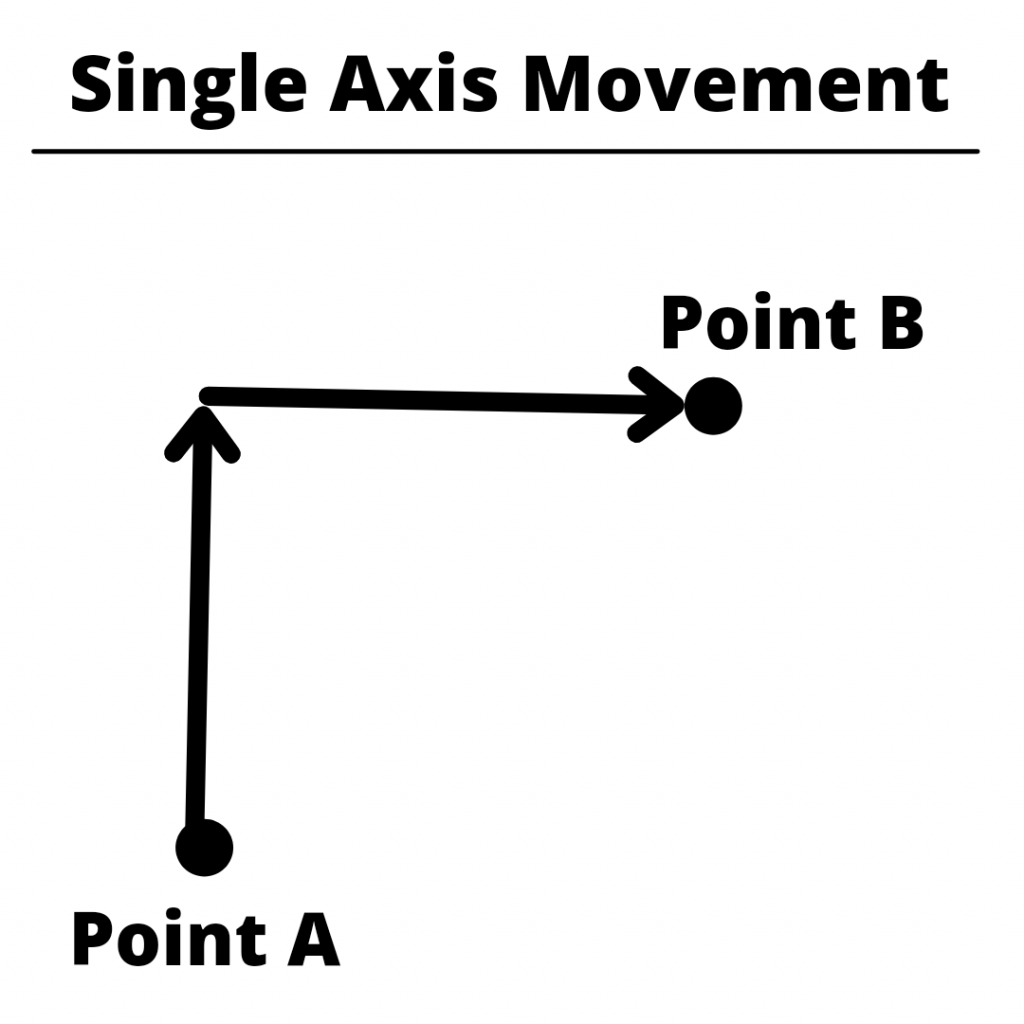

Newer CNCs will move in a true straight line fashion, however some older CNCs can process the command in different ways.

Some machines may only move one axis at a time while others will move in other strange ways. The most important thing is to be aware how your specific CNC control will process the rapid travel command and create your program to account for this movement.

Because various machines will process commands in different ways, this means you may not be able to take a program and a setup and run it on a different machine.

What is the G code for rapid traverse?

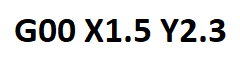

The G code for rapid movement is G00.

This applies to both CNC mills and lathes.

In the example above, G00 is the code for rapid traverse and the X and Y values are the position that the machine is to rapidly move to.

Rapid movement can happen in the Z axis as well.

What should you think about when using rapid travel?

When you are zipping your CNC back and forth think about:

- Part location – it can be easy to forget about a step in your part and attempt to move over the top of you part at a Z height that is too low

- Fixturing – similar to your part location, remember that you often have clamps, vises, etc. that will be in your machine and it’s best to avoid them

- Removing material – don’t cut in rapid mode, it will result in size issues and poor surface finishes at best

Rapid traverse in manual machining

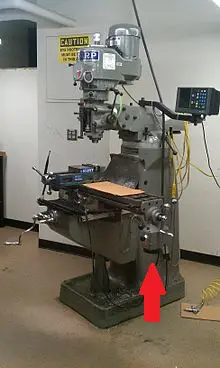

Many manual machines, such as a Bridgeport mill, use a power feed to rapidly move around the workpiece.

These power feeds are not as fast as a CNCs rapid moves but they are still much quicker than the standard speed which usually involves cranking a handle to position the machine.

Related articles

For more information see these related articles: