What does the M98 code do?

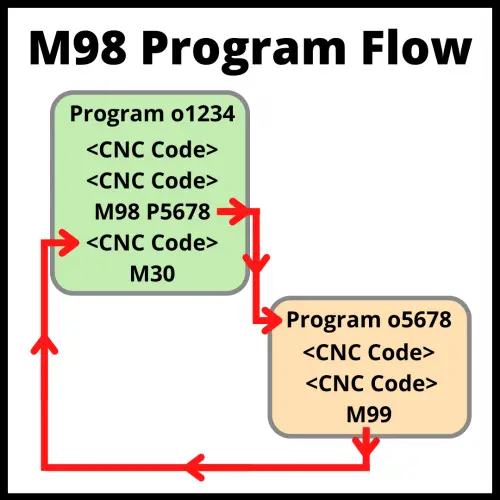

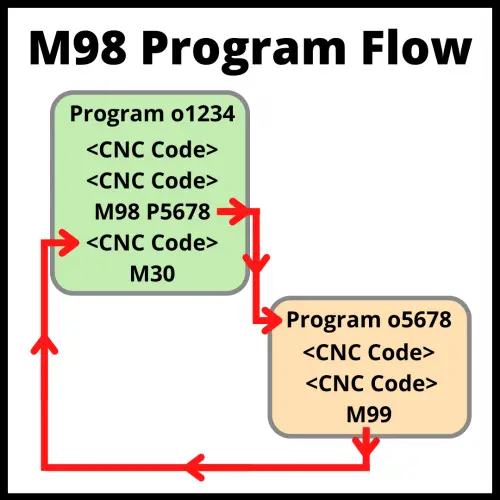

The M98 CNC code is a subprogram call by program number.

This means that the machine will run a separate program stored on the machine.

The machine will jump from the line in the current program to the start of the subprogram called up with the M98 code.

At the end of the subprogram, the M99 code will be used. This signifies then end of the subprogram.

Once the machine reads the M99 code, it will return to the line in the original program where the M98 code was used.

The machine will continue reading the program starting with the line after the M98 code.

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!

Other codes used with the M98 code

- P – Selects the subprogram number to run. When used with M98, the P code selects the program number to run

- O – Identifies the program number

- M99 – Ends the subprogram, returns to the line after where subprogram was run

- L – Number of times to repeat the subprogram

Format for using an M98 code

Here is an example of an M98 code in use:

M98 P5678 L2

This line of code will tell the machine to go run program number 5678 two times. The L code tells the CNC machine to run the subprogram twice.

The L code can be left out if the subprogram will only be run once.

Program 5678 will perform any necessary machining functions and then end with an M99 command instead of M30.

The M99 command will make the machine return to the line after the example shown above.

On the other hand, both commands (M98 and M97) use parameters K (or L) as the number of repetitions of a given subprogram.

The use of the letter K or L depends on the CNC model. Always check the machine’s manual for further details.

What are subprograms used for?

Subprograms are a separate CNC program selected to run from within another program.

They are used to perform repetitive machining operations or sequences such as drilling, counterboring and countersinking a hole.

They can also be used for machine related functions such as preparing for a tool change.

CNC machines run the lines of code in a program in order.

Using subprograms allows the programmer to jump around to different sections of the current program or to run a different program and come back to the current program.

Differences between a subprogram and the main program

The commands to end the main program and a subprogram are different.

The main CNC program ends with either M30 code (for most machines) or M02 (for older machines). No further code will be run after either of these codes.

A subprogram ends with the M99 command.

When using the M98 command, M99 returns the machine to the line in the original program which called the subprogram. The machine will continue to run code in the program from that point.

Let’s look at that program flow again to see how the machine moves from the subprogram call (M98) to the subprogram and back to the main program after the M99 code.

Benefits of using a subprogram

The greatest benefit of using subprograms is reducing the lines of code which makes the program easier to read and edit.

Subprograms can also reduce the number of errors in the program. Less lines of code means less possible sources of problems.

Drawbacks to using a subprogram

Subprograms are meant to make the program easier to work with for both the programmer and anyone using it. If not done correctly, they can have the opposite effect.

Programmers should remember that part of their job is making sure that the program is easy to use for the operator.

It can also be easy to have the wrong modal commands or offsets chosen when starting or ending a subprogram.

Following a good program format that uses safety lines or blocks of code can protect from this happening.

If it is important that a mode or offset is needed in a specific section of your program, it is best to use the necessary code to make sure things are set correctly.

Assuming your machine is in the correct mode already is dangerous. Set the correct modes when you need them.

Making subprograms inside your subprograms (nesting) also has the potential to cause confusion. Repeatedly switching between programs can be confusing for both programmers and operators.

For a more in-depth description of subprogram nesting, see additional info on the topic further down in this post.

M97 vs M98

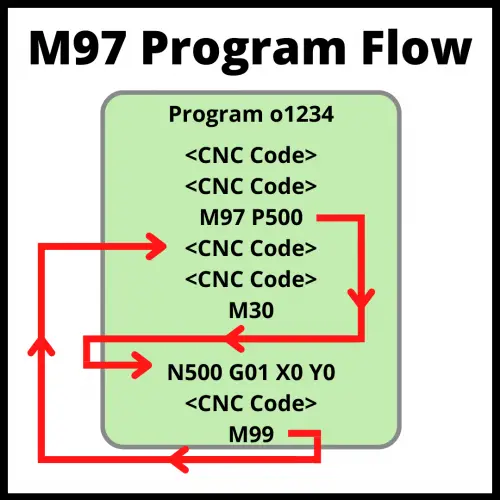

There are two ways to run subprograms: M97 and M98.

The difference between M97 and M98 is the program location they move to.

M97 will jump to a new line in the current program.

M98 will run an entirely different program.

Frequently asked questions about the M98 code

How do modal commands work in subprograms?

Modal commands work the same way as they do in the main program. This means they stay on until changed or turned off.

If a modal command is on when starting the subprogram, it will stay on while running the subprogram. The same is true when switching from the subprogram to the main program.

The safest thing to do is make sure your safety blocks cover the required codes for each section of code.

What is nesting?

So far, we have concentrated on running a subprogram from our main program, but did you know you can also run a subprogram from within a subprogram?

This is called nesting.

Nesting can be a powerful tool but can quickly get out of control.

Most CNC controllers will allow up to four level deep nesting.

This means calling a subprogram in a subprogram in a subprogram in a subprogram in your main program.

Confusing right? That is why in most cases it isn’t a good idea to nest that deep. For most applications, one level deep is enough.

Even two level nesting can be hard to follow. Three and four levels are definitely not advised if you are reading this post which is aimed at beginners.

Tips for numbering your subprograms

Create a system for numbering your programs and subprograms to avoid confusion.

Some choose to set aside blocks of numbers for each type of program. For example, O0001-O4999 for main programs and O5000-O9999 for subprograms.

Others make their subprograms closely follow their main program numbers. If the main program is O1000 then the subprograms will be O1001, O1002 and so on.

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!