Welcome to the exciting world of CNC programming!

If you’re curious about the O CNC code and want to learn how to use it, you’ve come to the right place.

In this easy-to-follow guide, we’ll teach you everything you need to know. Don’t worry if you’re new to this, because the O code is super easy to learn.

So, let’s jump in to discover the O CNC code together!

What does the O code do?

The O code lists the CNC program number.

It is found on the first line of a CNC program.

Example program numbers

| Code Block | Program Number |

|---|---|

| O0001 | 1 |

| O1234 | 1234 |

| O0555 | 555 |

What range of numbers can you use with the O code?

Most controllers allow the use of program numbers O0001 through O9999.

Some newer machines allow a larger range of program numbers, but they would rarely be used or needed.

O code program example

| Code Block | Code Description |

|---|---|

| O0001 | (Program number: O0001) |

| G90 G80 | (Absolute positioning mode, cancel canned cycles) |

| G54 G0 X0 Y0 | (Select coordinate system G54, rapid move to X0 Y0) |

| M3 S1000 | (Start spindle clockwise at 1000 RPM) |

| G43 H1 Z0.1 | (Tool length compensation active, move Z to 0.1) |

| G1 Z-0.5 F100 | (Linear move to Z-0.5 at a feed rate of 100) |

| X1 Y1 | (Linear move to X1 Y1) |

| X0 Y0 | (Linear move back to X0 Y0) |

| G0 Z1 | (Rapid move to Z1, retracting the tool) |

| M30 | (End of program and rewind) |

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!

Using the O code when running subprograms with M97 and M98

Subprograms are reusable pieces of code that are often used for repetitive tasks such as drilling holes or changing a tool.

There are two codes used to call subprograms; M97 & M98.

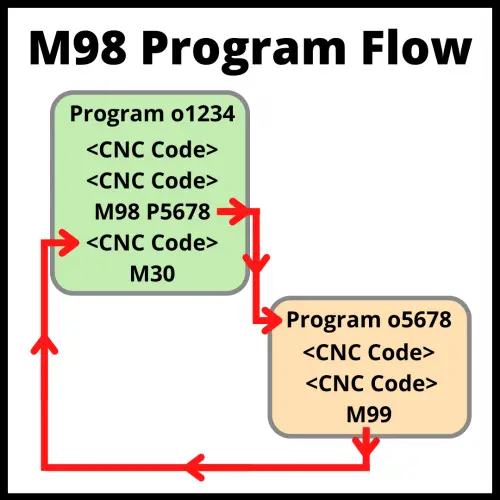

When using M98, the P code is used to choose the subprogram to be run.

For example, M98 P5678 will tell the CNC to run subprogram O5678.

M98 calls a separate program.

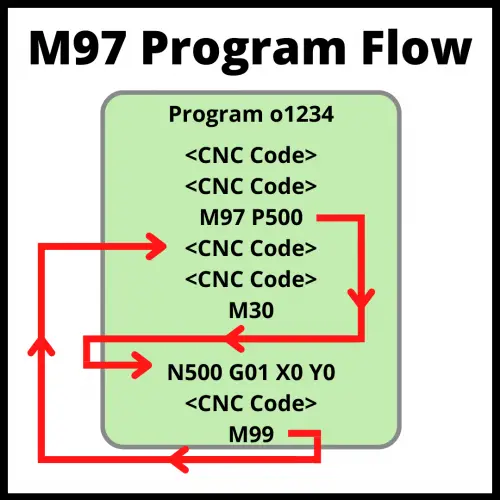

The M97 code calls a subprogram by line number in the current program.

Important: M97 and M98 call subprograms differently. M97 jumps to another line in the current program. M98 moves to a completely separate program.

An example of this is M97 P500 will tell the machine to jump to line number 500 in the current program. The N code notes the line number.

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!