What is CNC programming?

CNC programming is the process of creating and running a program consisting of G code in a CNC machine to move the machine and control its functions.

There are a large range of CNC machine types available, from industrial mills and lathes to home machines such as 3d printers, laser engravers and CNC routers.

All of these CNC machines use the same G code language to control the machine.

How difficult is it to learn CNC programming?

Learning basic CNC programming is fairly easy. It involves learning how the CNC machine will react to a series of codes. Most of the codes are easy to remember with a little practice (F for feedrate, S for spindle speed) and for any of the harder to remember codes, cheat sheet type references are usually not too far away.

Learning advanced CNC programming will take more time. Practice and repetition help, as does attending local training programs or completing an online training course.

When learning CNC programming expect to apply math skills, learn to read manufacturing blueprints and work with specialized computer programs.

Ready to master CNC programming?

Try the free 30 minute intro course to see how simple and easy G code can be. Take the shortcut to becoming a G Code Master today!

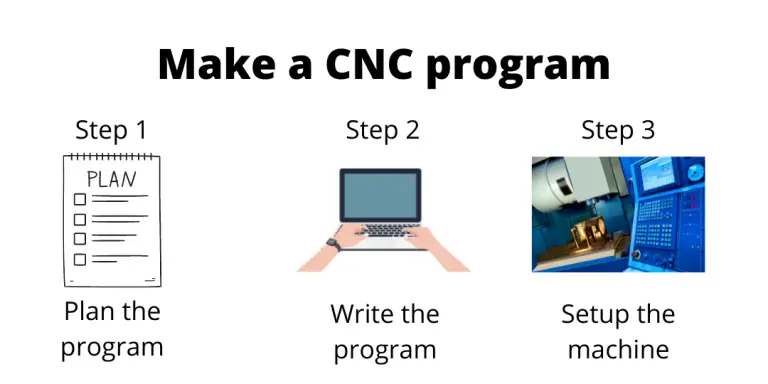

What are the steps involved in CNC programming?

Plan the program

The first step in CNC programming is planning out your program. In this step you will choose the machine and tools that will use to make your part. The operations to create the part (shape part, drill hole, mill slot, etc.) as well as the order of those steps will be determined.

Write the program

Now that you know what you will use to make the part (machine and tools) and how you will make the part (the order of operations), the program can be written.

When writing the program, you will create code either by hand or with the help of software to create the instructions for the machine to run.

In this step, documentation is usually created that lists any special requirements for running the program such as the tooling to be used, offset information, and fixturing information.

Setup the CNC machine

The role of the CNC programmer will sometimes end once the program is written and documented. However, in many machine shops programmers are also responsible for setting up and/or operating the machines too.

Setting the CNC machine up will involve loading the correct tools, setting offsets, loading the program and running a first piece to verify everything is running as planned.

Types of CNC programming

Manual programming

Manual programming is when the programmer creates the G code by hand. This involves controlling all of the machine’s functions and movements through the use of code.

Manual programming of CNC programs is usually only done with very simple programs.

Conversational programming

Conversational programming involves giving the machine specific parameters or dimensions that are required and the CNC machine generates the code for you based on the input.

Conversational programming is a middle point between manual programming and programming with CAD/CAM systems. Conversational programming simplifies the programming of features that may be difficult to program manually.

Conversational programming can allow quicker programming times when compared to CAD/CAM programming options. It also generally requires far less training than what is required to work with CAD/CAM packages.

Programming with CAD/CAM

The majority of CNC programming today is done with the use of various computer aided drafting (CAD) and computer aided manufacturing (CAM) software packages. These software programs allow the creation of long, complex CNC programs with much less work when compared to manual or conversational programming.

CAD/CAM programs are capable of programming things that wouldn’t be possible with manual or conversational programming. There are many different CAD/CAM software programs available with some of the most common being AutoCAD, Fusion 360, SolidWorks, Mastercam & EDGECAM.

How to start learning CNC programming

Local college/training

One of the best ways to start learning CNC machining is to look for local education resources such as colleges, community colleges, training programs and your state’s manufacturing extension partnership (MEP).

These resources often provide unequaled instruction and hands on use of equipment.

In some areas, companies have created their own training programs which they operate to help educate their local workforce.

Self-guided training

If you don’t have local training options available, there are a large number of resources that allow you to learn CNC machining and programming on your own schedule.

YouTube has a wealth of informative instructional videos and there is an abundance of information available on other online resources such as MachinistGuides.com.

We recommend reviewing our list of the Best CNC and Machining Books to find the best reference material available.

Learning on your own can be daunting, especially when you don’t know where to start. For this reason, we have put together A Roadmap to Learn CNC Programming to help guide you and make sure you focus on the important stuff first.

Online training

For those looking for a more structured approach, there are online CNC training resources and courses available such as GCodeTutor.

The biggest benefit of online training is that it allows you to work at your own pace. The best online training programs will have help resources available as well as quizzes and projects to test your knowledge.

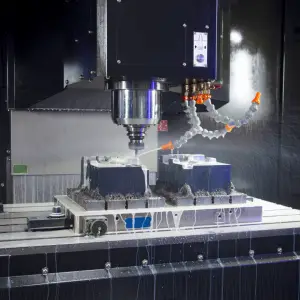

Types of CNC machines

CNC machines used to be extremely expensive machines that only large companies were capable of purchasing.

In recent years, the cost of CNC machines has come down quite a bit. Large scale industrial machines are still available, but they are accompanied by a new generation of machines aimed at hobbyists and makers.

Home/hobbyist machines

- CNC routers

- CNC plasma cutters

- CNC laser engravers

- 3d printers

Industrial level machines

- Mills

- Lathes

- Electrical discharge machines (EDM)

Frequently asked questions

Do you need a degree to get a job in CNC programming?

No degree is needed to become a CNC programmer, although previous training or certifications are looked at very favorably by employers.

Many employers are willing to provide on the job training to teach new employees the skills needed to perform the job.

How long does it take to learn CNC programming?

The basics of CNC programming can be learned in a short amount of time. Learning the basics will only take a few short months.

However, CNC programming is a wide field, and it will take much longer to have a solid understanding of everything that goes into CNC programming.

To become a highly skilled CNC programmer will likely take years. Training programs vary in length from 1-4 years on average. In addition, hands on experience will be needed to truly become a master of the craft. Certainly, anyone who applies themselves and works hard to learn will shorten that timeframe considerably especially when working in a good training program.

Is CNC programming a good career?

CNC programming is a great potential career. There is a high level of demand for skilled CNC workers across the globe. Many experienced CNC programmers and machinists are expected to retire in the coming years and a lower rate of younger workers entering the field has created a high demand for skilled CNC workers.

The demand for skilled CNC workers is so large that many in the CNC industry refer to it as “the skills gap”.

This skills gap has created a good opportunity for anyone seeking a well-paying job in the industry.

What is the salary for a CNC programmer?

According to GlassDoor.com, the average CNC programmer makes about $85,000 per year.

That comes out to about $40 an hour.

CNC programming is similar to other skilled trade jobs and can pay quite well without the need for a college degree. Getting training or certifications will help improve your chances of landing that well-paying position.

What skills does a CNC programmer need?

Because most CNC programming positions require the use of specialized CAD/CAM software, the best programmers have solid computer skills.

CNC programming positions often require math skills as well. Trigonometry, geometry and algebra are all commonly used when programming. Often the computer software will perform the necessary calculations but there are many times where calculations must be verified by hand.

Luckily, most of the math skills only use a limited number of formulas. To get a better idea of the type of math skills involved, check out our Beginner’s Guide to Machine Shop Math.

What other jobs take similar skills to CNC programming?

CNC and machine operators are the closest related job to CNC programming. Often, operators are the ones who will be running the CNC programs.

It is quite common for operators to gain some experience in their machine shop and work their way up to a position in CNC programming.

CNC and machine operator positions are typically much less demanding when it comes to computer and math skills and are a great starting point for anyone interested in learning CNC machining.