Every trade has its own toolset. Mechanics, carpenters, and electricians all have special tools associated with the profession. Being a machinist is no different.

There are many tools that a machinist uses in their everyday work. Below is a list of the most important tools for a machinist to own along with some tips to consider.

My quality control experience probably makes me biased, but the most important tools you can have are pieces of inspection equipment. The logo says it all, “If you can’t check it, you can’t make it”

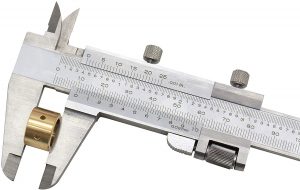

Caliper

Calipers come in many forms. The most common types are vernier calipers, dial calipers and digital calipers.

For a long time, the best choice was dial or vernier. This was largely because digital calipers were prohibitively expensive. Times have changed.

Nowadays, a quality digital caliper can be had for as low as $25! Even the top quality, super dependable digital calipers aren’t that expensive anymore.

I always recommend that anyone thinking about a caliper at least considers a digital caliper. The only real downside is batteries die.

The truth is they die, but not that often. The budget calipers have batteries that last months. The top shelf calipers from manufacturers such as Mitutoyo have batteries that last years.

Enough about digital calipers already.

Dial calipers are nice option too because they don’t have any electronics to die. What they do have is moving parts. Keep them clean though and you shouldn’t have any problems.

In fact, keep all your tools and gauges clean! This is important.

Dial calipers are fairly easy to read, though in my opinion still slower. I doubt fractions of a second matter but personally I prefer the instant measurement of a digital caliper.

The best comparison of the difference taking a measurement with a dial caliper to a digital caliper is a normal analog clock to a digital clock. There is very little time in the calculation of the value, but it is there.

The last type of calipers are vernier calipers. Don’t get mad at me (OK, yell at me in the comments if you must) but I don’t like them. They take far too long to read. Maybe it’s because I haven’t practiced with them enough, but I don’t see the benefit. I keep my tools clean and have never had an issue the moving parts of a dial caliper. Never had an issue with a digital caliper either. With all the pros and cons and constant rush, rush, rush of your typical machine shop, I have always preferred digital options.

In the end it is all about personal preference. There is nothing wrong with vernier, dial or digital calipers. If you pick a quality tool, then they will all take reliable measurements.

If you are just starting out, I recommend going with digital calipers to lessen the learning curve and speed up measurement reading, but keep in mind that this isn’t a huge jump in speed.

Outside micrometer

A 0-1” micrometer is hugely important for machining. Calipers may get more use but it is only due to their versatility. Calipers can measure inside and outside dimensions along with depth measurements. When we talk about micrometers, generally we are talking about outside micrometers.

Still…

A 0-1” micrometer is going to compete pretty fiercely with a 0-6” caliper in everyday use.

Normally, a 0-1” micrometer will measure 10x tighter tolerances at .0001” increments and a caliper will measure at .001” increments. For this reason, a good micrometer is vitally important to have.

Getting the best micrometer you can afford in the 0-1” measuring range is a good idea. If budget is a concern, going a little cheaper for larger sizes that won’t be used as often is wise. A decent 0-6” micrometer set from someone like Anytime Tools will perform almost as well as one from companies like Starrett or Mitutoyo at a fraction of the price.

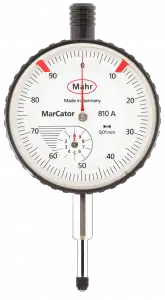

Dial indicator

Dial indicators come in a few different forms including dial test indicators and drop indicators.

Dial test indicators work great for inspecting tight tolerances of specific features on a part. The downside is that they will often take more time to setup when compared to using a caliper or micrometer.

Dial test indicators can also be used to check the form of surfaces. Flatness, parallelism and total indicator runout (TIR) are just a few of the feature controls that can be measured.

Another application for dial test indicators is to align setups both in machining and inspection.

Dial test indicators are available in assorted accuracies such as .001”, .0005” and .0001” with even higher precision models available.

Drop indicators are generally used as part of a snap gauge or another type of inspection fixture. They are often used when a specific dimension(s) needs to be measured very accurately.

Parts being run to a tight thickness tolerance could be checked with the use of a drop indicator attached to a height stand. A setup such as this would allow the inspection of a large number of parts to a high degree of accuracy.

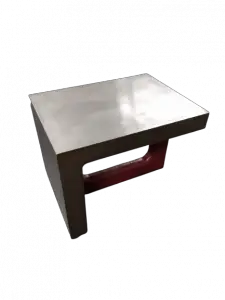

Surface plate

Surface plates are the accurate reference that so many measurements are taken from. They are essential for inspection work. This isn’t something you need to own but it is something you will want access to.

Surface plates come in a wide variety of sizes (usually 6” or 12” increments) along with multiple accuracy grades (AA, A & B). While smaller surface pates are reasonably priced, they get exponentially more expensive as the size increases.

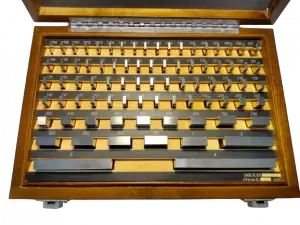

Gauge blocks

Unless you are only doing very light machining work, you will want a good set of gauge blocks. If you are working in a machine shop, then you already know that you need calibrated gauge blocks to check your tools.

For home use, a gauge block set is good to have when working with indicators or tight tolerances (< 0.001”). In a shop atmosphere, the gauge blocks will be sent out at a set frequency to be calibrated by a calibration laboratory, but this is overkill for most hobbyist. Just follow one simple tip.

If you notice corrosion on your gauge blocks, think about replacing them. If kept clean and out of harm’s way, they should last a very long time.

The best way to protect your gauge blocks is to store them in a safe, dry place where the temperature is relatively stable. Extreme heat or cold will affect the size of the gauge blocks as the material (usually steel) expands and contracts due to temperature swings.

Depth micrometer

Depth micrometers are great for measuring hole and slot depths along with various location or thickness checks. The downside to depth micrometers is that they are not as versatile as many other tools and are substantially more expensive.

Depth micrometers will not get as much use either which moves them down the list in importance. Because they don’t get used as much, a 0-3” set can be a good starting point for beginners or 0-6” set if you want to go all out. Don’t spring for a full 0-12” set unless you know you truly need it because it will set you back a pretty penny.

Take good care of your depth micrometer because the thinner rods or blades of some depth micrometers can be bent rather easily which will affect the accuracy of the tool.

Steel ruler

It can be easy to overlook the importance a decent ruler but it is an excellent tool to use in laying out your work. No need to break the bank, just find one you trust. Starrett has made good ones for a long time.

One tip: don’t leave it in your pocket. Too many rulers have been broken because someone left the ruler in their pocket and sat down on it.

A tape measure can work too but if taken care of you’ll find that a quality steel ruler will last much longer.

Pocket comparator

Sometimes called an eye loupe, pocket comparators are invaluable for checking chamfers, bevels and features with very loose tolerances. Inevitably, someone will over spec a chamfer that could simply be a break edge and this will be the tool you’ll need to measure it.

Most pocket comparators have reticles that can be changed also. This is good for when the reticle becomes too scratched from use.

Something to think about: White reticles can be handy to use when measuring darker materials that make seeing a standard black lined reticle almost impossible.

Toolbox

With all these quality tools hanging around, it is a good idea to keep them safe. Having a nice toolbox to put them away safely will do wonders for protecting them for years to come.

Look for one that is lockable because good tools have a bad habit of walking away in some shops.

A good benchtop box is a solid start, no need to go all out with a huge rolling cabinet.

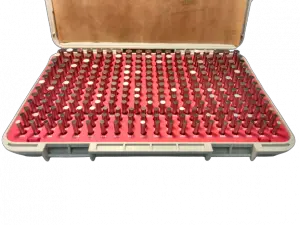

Gauge pins

Gauge pins are a great tool for measuring hole sizes among other uses. They are also good to use for calibrating other tools such as your micrometers or for use in creating inspection fixtures.

Telescoping bore gauges

Telescoping gauges are used in conjunction with micrometers to check measurements of internal features such as slots or holes.

The gauge is opened up and locked in place then a micrometer is used to check the measured size once the gauge is removed.

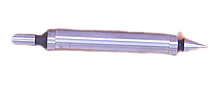

Edge finder

Edge finders are commonly used for locating workpieces when setting up for milling. While spinning, they can be slowly moved towards the workpiece until they are forced off center by the pressure from the workpiece.

Once this happens, you know that the edge of your part is one half of the diameter of your edge finder away from the current machines position.

Deburring tool

Anyone who has worked in the machine trade knows the pain that comes with slicing your hand on a razor sharp metal burr.

These wonderful little gadgets zip that bad boy right off to protect you and the part. Most shops will have a deburring tool at every machine station.

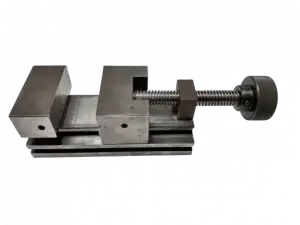

Machinist vise

There are many different types of work-holding equipment for a machinist to use. Various vises for different situations.

Benchtop vises are great for hand operations such as filing or modifying tooling.

Precision vises such as a flanged or swivel vise are great for use when machining. Vises are excellent tools for inspection use also.

V block

V blocks are indispensable for inspection purposes. They are perfect for holding round parts especially during inspection operations. Many parts will be placed in a v block and rotated for runout, circularity, cylindricity and concentricity checks.

Machinist square

Simple machinist squares are great for layout work. Combination squares allow you to do even more complex operations. They aren’t meant for use with extremely precise tolerances.

Precision/vernier protractors fit in this same category and are mostly for reference only.

Right angle plate/knee block

Knee blocks allow a workpiece to be located in different positions by clamping it to the knee block at various angles.

It is useful in the inspection of many parts to have a known square surface.

Engraving pen

All of these much needed tools unfortunately have a habit of disappearing when you need them most. A good engraving pen comes in handy for marking your property.

Double up by stashing your tools in a lockable toolbox and marking them with your name.

Other tools

Did we forget any critical machining and/or inspection tools? If so please let us know in the comments below.

Things to consider

Which tools are best for a beginner machinist to start with?

The best tools to start with are a good set of calipers and a quality 0-1″ micrometer. After that, a couple indicators with varying accuracies and a depth micrometer will be the best additions.

What you need beyond these initial tools will largely depend on the work you are doing, but larger micrometers (like a 0-6″ set) and a set of bore gauges will likely be needed.

Where can you buy used machinist tools?

Used machinist tools can be purchased from a variety of sources. Craigslist and eBay are great sites to watch. Yard sales and estate sales are an often overlooked place to score nice tools.

Related articles

For more information check out these related articles: