Table of Contents

ToggleWhat is a full radius?

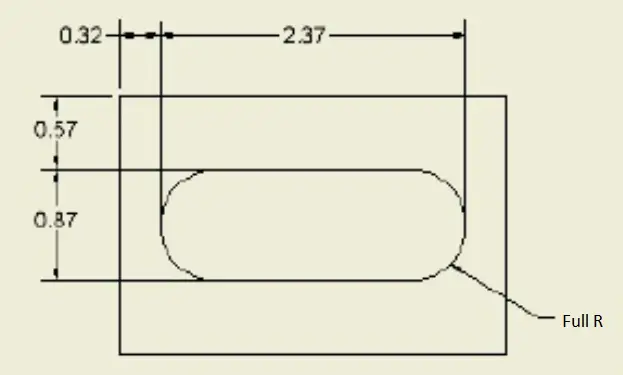

A full radius is a radius that smoothly blends into another surface. Full radius is most often specified in a rounded slot feature or a feature that mimics a rounded slot.

A full radius sometimes noted as a true radius or full R is outdated language and not part of the current revision of the drawing standard ASME Y14.5. The full radius callout is referencing a smooth transition from the radius to an adjacent surface.

How to measure a full radius

Because no reference standard documents the requirements of a full radius, there are no specific requirements for the callout.

When a full radius, true radius or full R is called out on the drawing, the blueprint drafter is attempting to control the blend into and out of the specified radius.

What is a full radius?

A full radius is a radius that smoothly blends into another surface. Full radius is most often specified in a rounded slot feature or a feature that mimics a rounded slot.

A full radius sometimes noted as a true radius or full R is outdated language and not part of the current revision of the drawing standard ASME Y14.5. The full radius callout is referencing a smooth transition from the radius to an adjacent surface.

How to measure a full radius

Because no reference standard documents the requirements of a full radius, there are no specific requirements for the callout.

When a full radius, true radius or full R is called out on the drawing, the blueprint drafter is attempting to control the blend into and out of the specified radius.

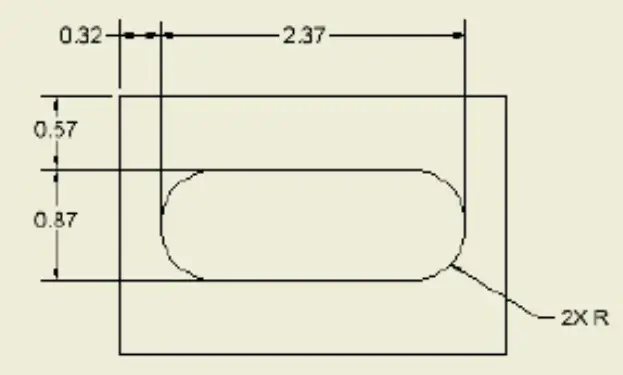

Full radius vs radius

There is no difference between the drawing callouts of full radius, true radius and radius. Because there are no specific requirements for a full radius referenced by any drawing or GD&T standards, there is no difference in the requirements of a full radius or full R vs a radius or R. A full radius does not have a tolerance. A radius if drawn correctly will have some form of a +/- tolerance or be controlled through a GD&T requirement such as profile or cylindricity.

There is no difference between the requirements of the example below or the previous one.

Want to learn more?

GD&T is a complicated subject and understanding it correctly can be the difference between a perfect part and scrap.

The best way to learn GD&T is from experienced teachers who can break down the material into manageable pieces.

Luckily, we know someone.

And MachinistGuides.com readers get an exclusive discount on training!

Get the Best GD&T Training AvailableRelated Articles

For more information see these related articles:

- Best CNC and Machining Books

- Beginner’s Guide to Blueprint Reading

- How to Read Machine Shop Numbers & Values

- GD&T Symbols Quick Reference

Full radius vs radius

There is no difference between the drawing callouts of full radius, true radius and radius. Because there are no specific requirements for a full radius referenced by any drawing or GD&T standards, there is no difference in the requirements of a full radius or full R vs a radius or R. A full radius does not have a tolerance. A radius if drawn correctly will have some form of a +/- tolerance or be controlled through a GD&T requirement such as profile or cylindricity.

There is no difference between the requirements of the example below or the previous one.

Want to learn more?

GD&T is a complicated subject and understanding it correctly can be the difference between a perfect part and scrap.

The best way to learn GD&T is from experienced teachers who can break down the material into manageable pieces.

Luckily, we know someone.

And MachinistGuides.com readers get an exclusive discount on training!

Related Articles

For more information see these related articles:

How does one measure Full R for first article inspection? Based on the explanation above, is it safe to either leave it blank (not bubble it) or just add N/A on the result and move on?

Hi Chuk,

I would recommend identifying the attribute (bubbling) and then listing it as a pass/fail item.

Hope this helps,

Brandon