Besides your CNC machine itself, the next most important part of machining is the router bit.

Different bits make different cuts and have different jobs, and if you’re new to machining, navigating bits can be confusing. From the bare-bones essential bits for machining to the more specialized bits that you’ll use rarely, there’s a lot of information around bits that can confuse even the most seasoned machinists.

To clear things up, we’ve made what we hope is a handy guide to walk you through everything you need to know about bits while you’re getting started as a machinist.

While we don’t claim this article is comprehensive, we do think that when you’re done reading, you’ll be a lot more knowledgeable about bits than when you started.

Table of Contents

ToggleEssential bits

These are the bits to get started with. They will get the most use. As a result, they should be the first ones that you upgrade to better bits.

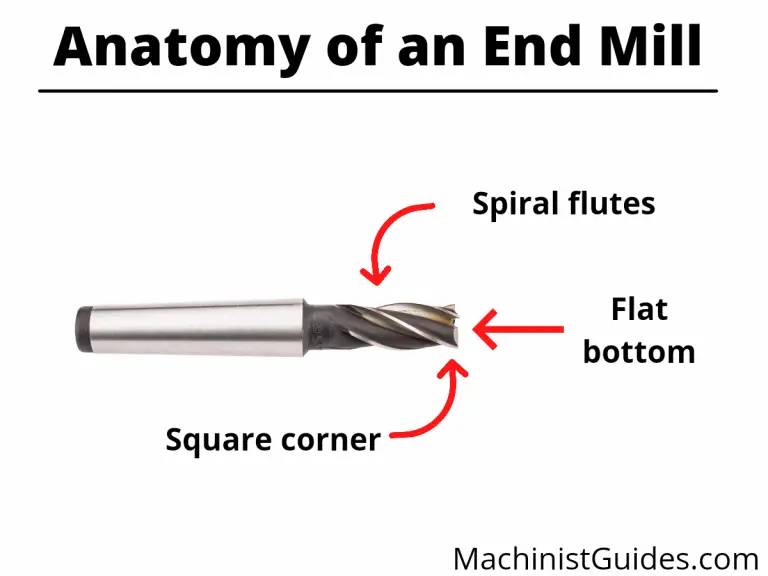

End mill

End mills are side-cutting tools, meaning they’re meant to cut flat bottoms.

They can cut a square slot or profile with a square corner, and you can also use them for contouring and reaming.

You’ll be able to distinguish an end mill by the flat bottom on the end of the bit.

V-bit

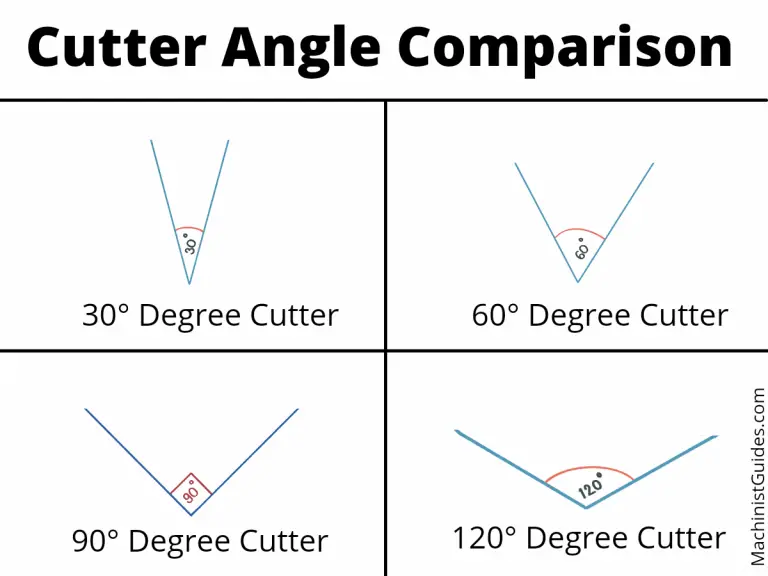

V-bits are – you guessed it – shaped like a “V.” Producing a V-shaped cut, these bits are great for engraving, lettering, detailed designs, and signs.

You’ll typically use V-bits to add your special style or artistic design to projects.

V-bits come in all different sizes and angles. The smaller the angle, the more narrow the cut.

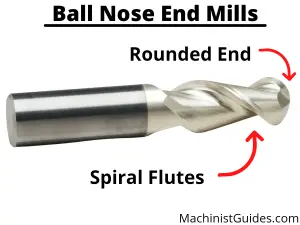

Ball nose end mill

A ball nose bit is basically the same thing as an end mill, except the end is a ball. This will give you a rounded contour around the edges of your cut.

You may also occasionally use a ball nose bit in lettering, but they are not as common as v-bits.

V-bits will allow you to create sharp-cornered letters, while ball nose bits will give you softer, rounded letters.

Surfacing bit

Surfacing bits are basically just big end mills.

You’ll use a surfacing bit to remove large amounts of material at once, like if you’re smoothing out your spoil board.

You can also use a surfacing bit to condition a bad piece of wood or otherwise smooth out the surface of the wood if it isn’t perfectly straight. This is very similar to planing a piece of wood.

Specialty bits

These specialty bits may not be necessary for CNC machining, but they’re nice to have handy.

Definitely don’t purchase any of these bits until you have the four essential ones above. But, once you have some experience under your belt, you can try a couple of these out to get more creative with your projects.

Carving bit

Carving bits are for any of you that want to make 2.5D or 3D projects. They allow you to make a lot of fine detail.

Some of the most amazing projects will use these bits. It will definitely be best to get some practice with not only your machine but also the software you are using as well before jumping into working with these bits.

You don’t want to be busting bits while you are still learning. Because of this, it is a good idea to start out with some cheaper practice bits while learning how to carve with your CNC.

T slot cutters

T Slot cutters are pretty simple: they’re made for cutting out slots on the back of a sign so you can hang it on a wall.

Signs of all sorts are common projects for anyone operating a CNC router. If you find yourself making plenty of signs, wall art or similar wall hangings then this bit will be an essential add to your tool box.

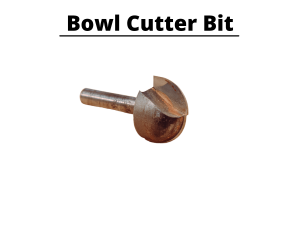

Bowl cutters

Imagine if a ball nose bit and a surfacing bit had a baby – that’s what bowl cutters are for. They will cut the same rounded shape as a ball nose. However, the bottom is wider and flatter than a ball nose because this bit is meant to remove a lot of material, like a surfacing bit.

These cutters are excellent for removing larger amounts of material or “hogging” out the material.

Engraving bit

Engraving bits are most often used to etch designs into glass, wood, acrylic, or metal.

The interesting thing about an engraving bit is that it’s a “drag” bit. This means the spindle isn’t actually turned on while the bit is in use. Instead, the bit just drags across the surface to engrave.

Cutting flutes

The spiral-shaped cutting edges on the sides of an end mill are called flutes. Generally, there are 2 flutes on CNC router bits, though there can be more. The more flutes there are, the better the finish you’ll get.

One misconception is that the more flutes you have, the faster you can feed material. Yes, extra flutes mean that you remove more material per spin, but it’s common for people to increase the speed too much and overload the tool.

In reality, you should slow things down when you have more flutes to avoid any overloading. So, while you’ll cut more material per spin with 5 flutes, the lower spin rate may mean that using fewer flutes is more efficient since you can cut faster with 2 flutes than you can with 5.

If you’re relatively new to machining, 2 flutes should be enough.

Types of flutes

Some of the stuff in this section is going to get pretty technical. While we’ll try our best to explain how the different flutes cut material, we also recommend watching a tutorial video for any bit where you have confusion.

Sometimes, it’s just easier to see a bit in action than it is to explain how the bit works.

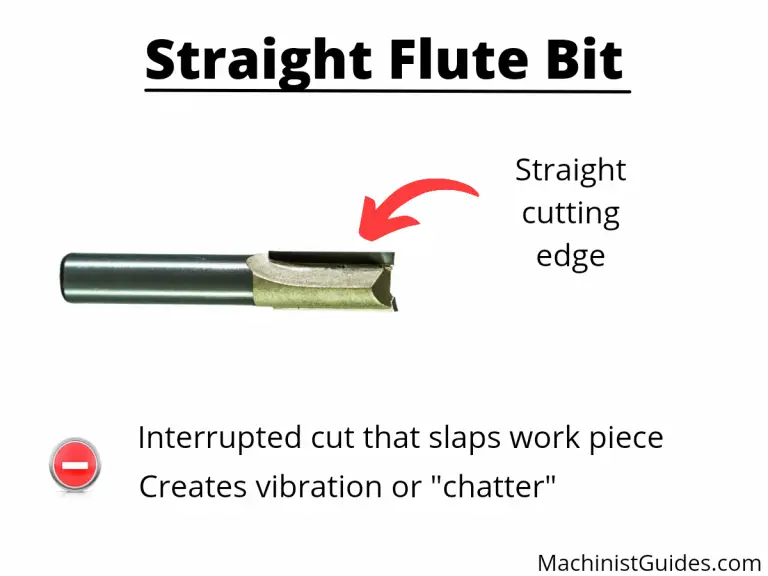

Straight

Straight flutes give you an interrupted cut that sheers away material for the entire length of the bit. Straight bits really slap the wood and cause a great deal of vibration and chatter. These bits require a lot of force and should generally be avoided unless you need them for a specific purpose.

Bowl cutters and surfacing bits are examples of straight flutes.

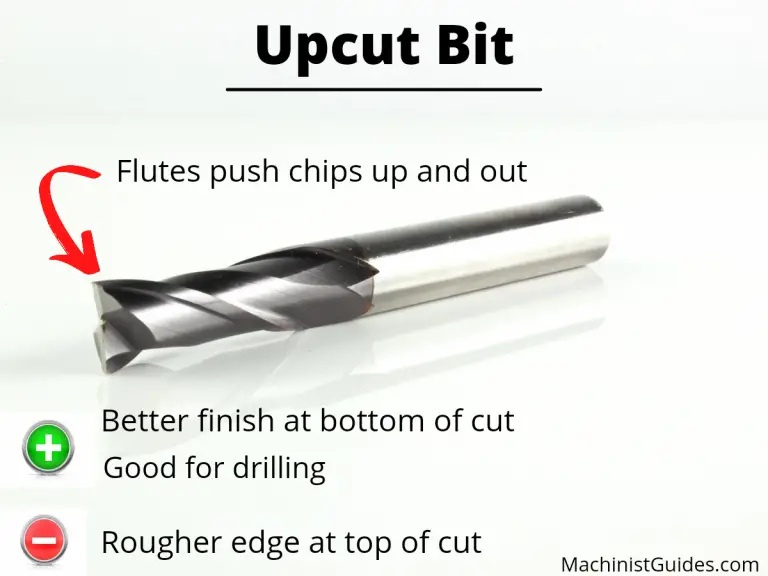

Upcut (up-spiral, upbit)

Upcut bits pull the chips up to remove them – the chips are “riding” up the flute. They pull the chips up towards the router or spindle.

Because the upcut is removing material out the top of the surface, the rough edge of the material you’re cutting is on top. Upcut bits have flat bottoms, which means they cut a smoother surface on the bottom.

These bits are great for drilling and plunging. They are not great for working with plywood because they will create a poor edge on the top of the wood.

Downcut (down-spiral, downbit)

Downcut bits are the reverse of the upcut bit. The material you’re removing is “pushed” downward away from the router or spindle. The rough edge, then, will be at the bottom of your material. The top edge of your material will be very clean when using a downcut bit.

Downcut bits are good for finish passes. However, you shouldn’t use downcuts for deep slots, drills or plunges. That’s because the downcut has no way of ejecting chips and debris, so it will stay stuck in the slot, or at least be very difficult to clean out.

While the downcut has a V-shaped bottom to leave room for the chips, the chips are not removed as well as a upcut bit and this can lead to heat buildup which can dull or ruin your bit.

Compression bit

Compression bits are a combination of Upcut and Downcut bits. A compression bit will have an upcut for the bottom quarter or third of the bit, while the rest of the bit will be downcut. When run at full depth, the compression bit will leave clean edges on both sides of your workpiece.

They can’t run as fast as upcut bits, but they are a nice compromise between finish edge quality and speed. They are a solid choice for working with veneered wood or plywood.

Router bit materials

When we’re talking about router bit materials, we’re really only talking about the cutting edge, as that is the most important aspect of a bit.

Carbide steel is a metal that is made with tungsten and a whole lot of carbon. The unique combination of materials, combined with how the metal is made gives this material a high tensile strength and high heat tolerance. Carbide steel also has high abrasion resistance.

In other words, carbide steel is good stuff. Naturally, it’s more expensive, but it’ll last 20-50x longer than a normal steel bit.

Compared to carbide steel, High Speed Steel bits are lower on the scale of tensile strength, heat tolerance, abrasion resistance, and price.

High speed steel is a little springy and generally has a worse finish than carbide steel. It also breaks down faster. Of course, then, high speed steel bits are cheaper.

There is nothing wrong with high speed steel bits but keep in mind that they will likely need to be changed or sharpened more often.

Router bit coatings

Coatings are chemical or metal finishes that have been bonded to the bit. Not all bits come with coatings, though it’s not at all uncommon to see coated bits.

One thing we should note is that coatings do not add strength to your bit. This is a common misconception. Coatings are intended to be heat barriers and are only a few atoms thick. To be honest, coatings are not always necessary, especially for hobbyists.

Because coatings often add expense to the bits and they aren’t needed for most users, we do not recommend them. However, if you think they are right for your application then by all means experiment and see what happens. For beginners though, we say skip them.

Black oxide bits are common and will protect against corrosion and friction. They are very similar to normal high speed steel (HSS) bits and work well for most materials.

Cobalt bits are made for greater heat resistance which works well when dealing with harder materials such as steel. These are overkill for working with soft materials such as wood and aluminum.

Tungsten carbide bits, which are generally just referred to as carbide bits, are extremely hard and heat resistant. Their hardness also makes them brittle, so you will want to use extra care when working with these bits, so they don’t chip. They can also be quite expensive.

Titanium bits are actually just high-speed steel bits that are coated with titanium nitride. This coating helps them to wear slower. This works well for heavy-duty, high-volume work. Once big downfall of titanium bits is that because they are coated and not solid titanium, they can’t be sharpened once they go dull.

All in all, we don’t really think it’s worth the additional cost for coatings. The benefits are rather minimal, especially if you’re just doing CNC as a hobby.

Router bit costs

To be honest, if you’re new to CNC, we recommend getting cheaper bits. Yes, they’ll dull faster, make lower-quality cuts, and don’t last long, but they make for good practice.

While you’re still getting a feel for machining, it’s not a bad idea to start off with cheaper bits. When you run them into your steel clamp and bust them into a million pieces, you won’t be nearly as disappointed.

Unless you forgot to wear your safety glasses. Always wear your safety glasses!

As you get better at machining, there will come a time where you should treat yourself to more expensive bits. They cut so much cleaner, and their high price is offset by the fact that they last a long time.

When you move on to the pricier bits, build up your arsenal by first starting with the essential bits we talked about earlier.

The first premium bits to get are:

- End mills

- V-bits

- Ball nose end mill

- Surfacing bit

Which router bits do you need to start with?

The essential CNC router bits

Flat Bottom End Mills:

- ¼”

- 1/8”

- 1/16”

The ¼” inch bit gets used the most, followed by the 1/8” and then the 1/16”

V Groove Cutters:

- 90 Degree

- 60 Degree

- 30 Degree

You’ll find other V groove bits besides these 3, but they aren’t necessary. Perhaps you’ll eventually want a 120 degree bit for larger lettering, but that’ll come down the road.

Remember the larger your V-bit angle is, the wider your lettering will be.

Ball Nose Bits

These bits are used for contouring and finer details such as when you are carving with your CNC.

Surfacing Bit

This bit is for flattening or “surfacing” your material. They work similar to a planer but they make the part flat in multiple passes.

They are also used for surfacing your spoilboard.

CNC router bits to buy later

These next few bits are nice to have but are nonessential. Hold off on purchasing these bits until you have a full set of the bits above.

Carving Bit

You have to be pretty advanced to get into carving. Carving projects have long run times, and you’ll likely need to learn a specialty program. Definitely hold off on carving until you’re ready.

Drag Bit

Unless you’re engraving metal or glass, you can hold off on buying a drag bit. They can be used to make some cool CNC projects but they only have a single use.

T Slot Cutter

These are handy if you’re making signs that you want to hang but are not a necessity.

Bowl Cutter

You won’t need this bit unless you’re contouring and removing a lot of material at once.

Practice bits and good bits

Surely you picked up on the concept, but we want to hammer home the importance of having practice bits, and sound, solid, expensive bits.

If you’re new or if you’re experimenting around, you should stick to cheap steel bits. This gives you margin for error and won’t leave you with much out of pocket when they break.

Once you’ve upgraded your skills and have a good handle on your machine, go ahead and upgrade your bits. But even if you’re confident in yourself, it never hurts to have some spare practice bits laying around.

Frequently asked questions

I'm new to routing, what bits are the most important?

If you skipped down to the bottom of this article and wound up here, go back up to the top and take a look at the first section. There, we went over the most essential bits in machining and explained what each essential bit is for. The most important bits to own are:

- End Mills

- V-bits

- Ball Nose bits

- Surfacing bit

Do I need coating bits for CNC routing?

Honestly, we don’t think coated bits are necessary. The coating layer is usually super thin, so you don’t get much out of the coating in the first place. And, coatings can make the bit’s cut less smooth.

To top things off, you can pay a heck of a lot of money for a coated bit, yet you likely won’t notice a difference in the cut.

thankyou for a clear concise and honest appraisal of my requirements.

having recently purchased a 3018 I look forward to a new learning experience.

Cheers.