Table of Contents

ToggleWhat is a blind hole?

A blind hole is a hole that does not go all the way through a part. A blind hole goes to a specified depth and stops.

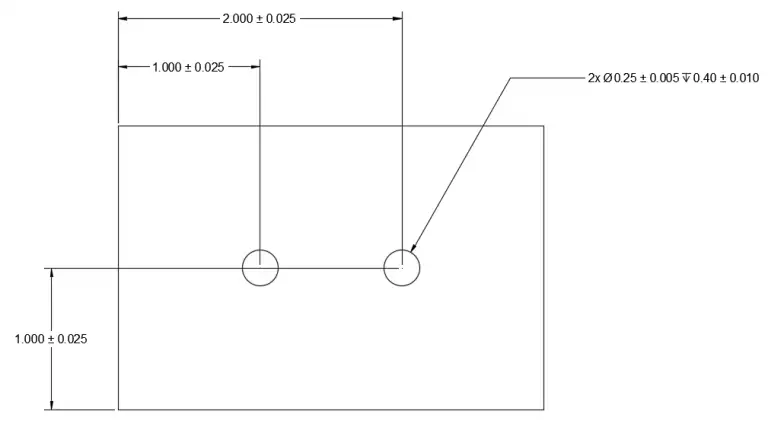

How to dimension a blind hole

To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain.

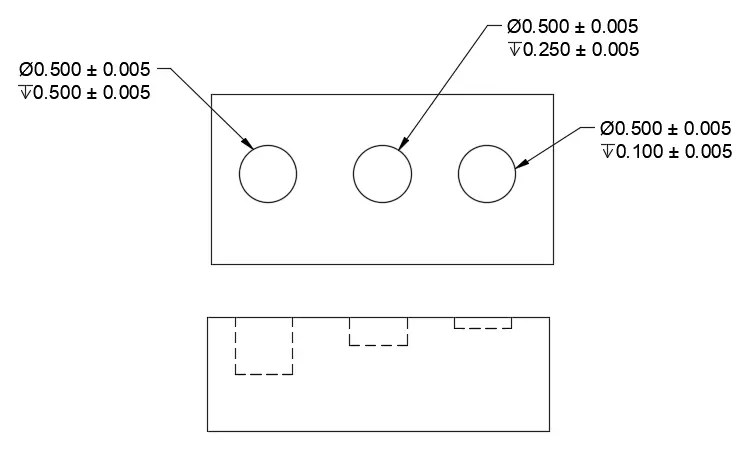

Blind hole vs thru hole

A thru hole, sometimes called a through hole, goes completely through a part. It has two open ends whereas a blind hole has one open end and does not break through to the opposite side. In the image above, the three holes on the left are all blind holes. The hole on the right is a thru hole.

Blind hole symbol

There is no GD&T symbol for a blind hole. A blind hole will be specified with a diameter and a depth specification or remaining amount of material. In the example below, the blind holes have a diameter of 0.25 and go to a depth of 0.40.

Can you make a flat-bottomed blind hole?

You can make a flat bottom blind hole, but it can be difficult depending upon what type of material is being drilled. A modified drill bit or an end mill can work. This video explains some tips.

Blind hole example

The example below has three blind holes. They all have a diameter of 0.500 but they have different depths. From left to right, the depths are 0.500, 0.250 and 0.100.

Want to learn more?

GD&T is a complicated subject and understanding it correctly can be the difference between a perfect part and scrap.

The best way to learn GD&T is from experienced teachers who can break down the material into manageable pieces.

Luckily, we know someone.

And MachinistGuides.com readers get an exclusive discount on training!

Related articles

For more information see these related articles: